Reference 3D laser scanning and 3D modeling / 2D alignment at Flender Industriegetriebe GmbH

3D laser scanning and 3D modeling / 2D alignment at Flender Industriegetriebe GmbH

Overview

Location: Penig, Saxony, Germany

Project duration: 4 months

Production area: 14.000 sqm

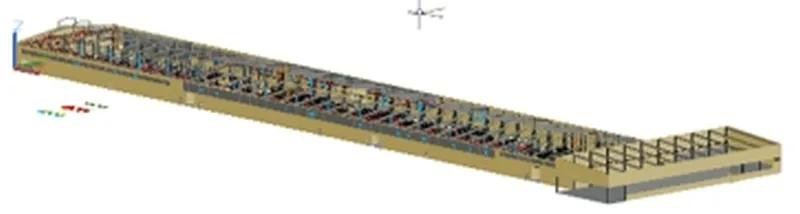

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented 3D laser scanning, 3D modeling and 2D alignment for Flender Industriegetriebe GmbH. The aim was to precisely record the existing situation, create a reliable overall 3D model and ensure the data interfaces for further planning and integration.

Project content

As-built survey using 3D laser scanning

High-resolution recording of the existing plant and building condition. Basis for precise modeling and reliable planning.

Scan data preparation

Registration, cleansing and structuring of the scan data. Quality assurance and coordinate reference for consistent further use.

3D computer-aided design (CAD)

Modeling of the trades 3D modeling of production facilities, cranes, buildings and technical infrastructure. Uniform level of detail for a clear, cross-trade view.

Overall model and hall models

Creation of a consistent overall model and individual hall models. Structured visualization for planning, coordination and documentation.

Unification of machine models

Derivation of individual machine models from the overall model. Targeted provision for specific planning and coordination tasks.

2D drawing comparison

Comparison of the 3D model with as-built drawings in 2D. Ensuring consistency, dimensional accuracy and completeness.

File transfer and Siemens NX compatibility

Ensuring the compatibility of models with Siemens NX. High-performance export and seamless data exchange with downstream systems.

Advantages of our solution

- Precision: High-resolution laser scans and structured data preparation increase the accuracy of as-built models.

- Planning transparency: 3D overall and hall models create a clear basis for decision-making for all trades.

- Integration capability: Siemens NX-compatible models facilitate collaboration and further processing.

- Consistency: 2D alignment ensures dimensional accuracy and reduces rework in planning and execution.

- Reusability: Isolated machine models accelerate variant creation and change planning.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>