Reference 3D laser scanning of factory premises and production halls at TRIMET Automotive Holding

3D laser scanning of factory premises and production halls at TRIMET Automotive Holding

Overview

Location: Harzgerode, Saxony-Anhalt, Germany

Scanning area: approx. 100,000 m²

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the 3D laser scanning of factory premises and production halls for TRIMET Automotive Holding. The aim was to create an up-to-date 2D plant layout and provide reliable 3D models of the halls, including machinery and equipment.

Project content

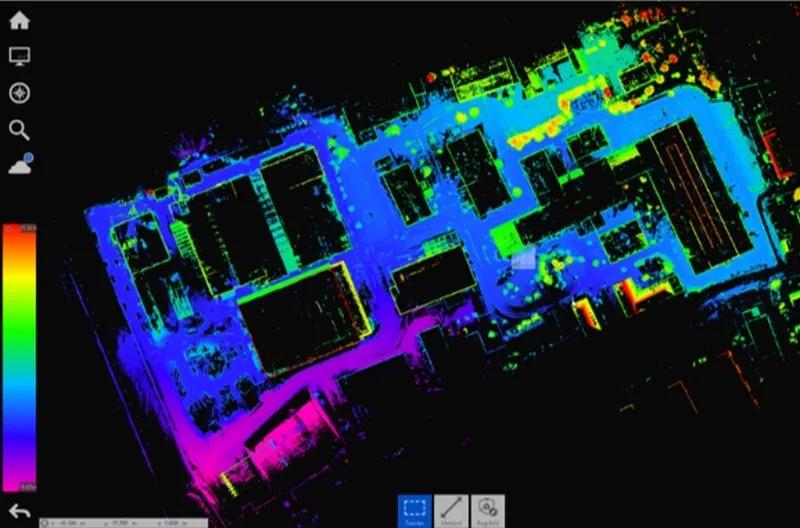

3D laser scanning of the plant site and halls

High-resolution mapping of the plant site and production halls covering approx. 100,000 square meters. Precise point clouds as the basis for layout and modeling.

Current 2D plant layout

Creation of a current 2D plant layout. Clear visualization of areas, path relationships and functional areas.

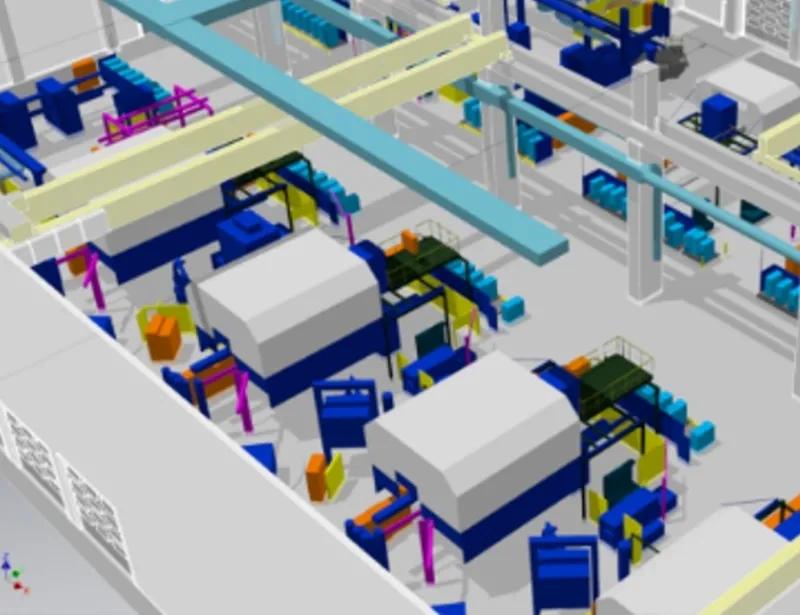

3D computer-aided design (CAD)

Hall modelling Modelling of the production halls in 3D. Structured geometries for a dimensionally accurate and consistent planning view.

3D CAD models of machines and systems

Capture and modeling of machines and systems. Standardized level of detail for transparent interfaces and subsequent further planning.

Advantages of our solution

- Precision: 3D laser scans provide exact as-built data and increase the dimensional accuracy of layouts and models.

- Transparency: Up-to-date 2D factory layouts and 3D models make surfaces, paths and interfaces visible at an early stage.

- Planning reliability: Consistent data bases make decisions easier and reduce rework during implementation.

- Reusability: Structured 3D models support variant creation and downstream engineering steps.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>