Reference Infrastructure Planning Final Assembly BMW G30 & G/J29 at MAGNA STEYR Fahrzeugtechnik

Infrastructure planning final assembly BMW G30 & G/J29 at MAGNA STEYR Fahrzeugtechnik

Overview

Location: Graz, Styria, Austria

Project duration: 12 months

Total volume: approx. 4 million €

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the infrastructure planning for the final assembly of the BMW G30 and G/J29 series for MAGNA STEYR Fahrzeugtechnik. The project aimed to plan secondary and media steel construction as well as process and plant media, prepare relocations and new buildings and ensure implementation through structured tendering and coordinated supplier monitoring.

Project content

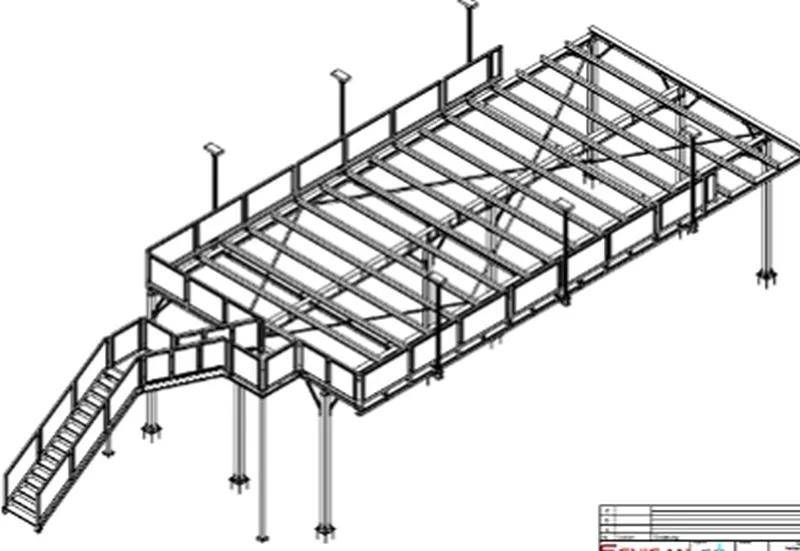

Infrastructure planning for secondary and media steel construction

Planning of secondary and media steel construction as well as process and plant media (compressed air, electrics, special media), lighting, extraction systems and social areas.

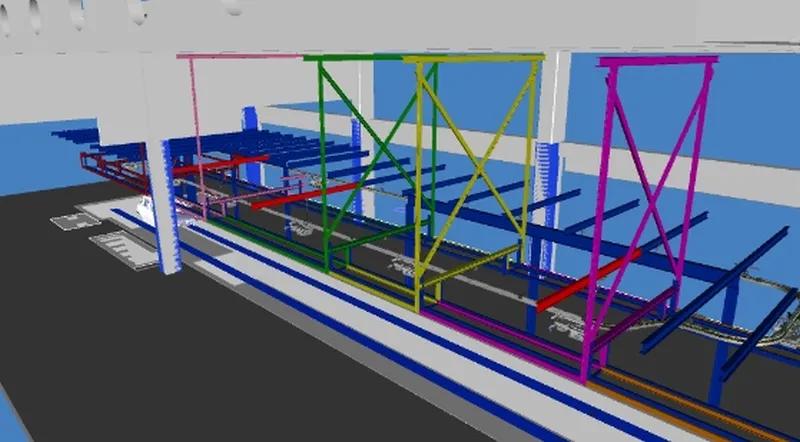

Conversion and new construction of infrastructure in assembly areas

Planning responsibility for partial conversion and new construction of infrastructure for assembly lines, pre-assembly, offline areas and plant and line supply.

Plant relocations and new builds

Preparation and coordination of plant relocations and new builds with clear interfaces and defined schedules.

Tendering, technical clarifications and tender review

Prepare tender documents, carry out technical clarifications and structured tender review. Procurement and processing of new orders.

Supplier coordination and monitoring

Supplier management and close coordination with peripheral departments during the realization phase. Ensuring quality, deadlines and interfaces.

Advantages of our solution

- Clear interfaces: Integrated planning of media steel construction, process and plant media, lighting and extraction systems reduces technical risks.

- On-time implementation: Structured tendering, tender review and supplier monitoring stabilize implementation and start dates.

- Investment transparency: Coordinated procurement and clear responsibilities ensure budget adherence in the total volume of approx. 4 million.

- Operational readiness: Planned conversions and new buildings as well as coordinated relocations enable the assembly areas to be commissioned quickly.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>