Reference Planning / realization of new coating plant and hall reconstruction at HÖRMANN Automotive Eislingen

Planning / realization of new coating plant and hall reconstruction at HÖRMANN Automotive Eislingen

Overview

Location: Ebersbach, Baden-Württemberg, Germany

Project duration: 21 months

Expansion of production area: 45 %

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the planning and realization of a new coating plant as well as the hall reconstruction for HÖRMANN Automotive Eislingen. The aim was to clarify interfaces, manage refurbishment measures across the entire site and design areas and layouts in a resilient manner.

Project content

Project management

Continuous project management across all phases. Clearly defined processes and responsibilities ensure deadlines, quality and budget.

Clarification of interfaces between construction trades and technological equipment

Structured clarification of interfaces between construction trades and technological equipment. Minimization of technical risks and smooth integration of the plant.

Refurbishment measures for the entire site

Planning and implementation of the refurbishment measures for the entire site. Coordination of the construction phases to reduce disruptions to ongoing operations.

Space dimensioning

Determination of space requirements for production, logistics and infrastructure. Orientation towards efficient plant structure and future expansions.

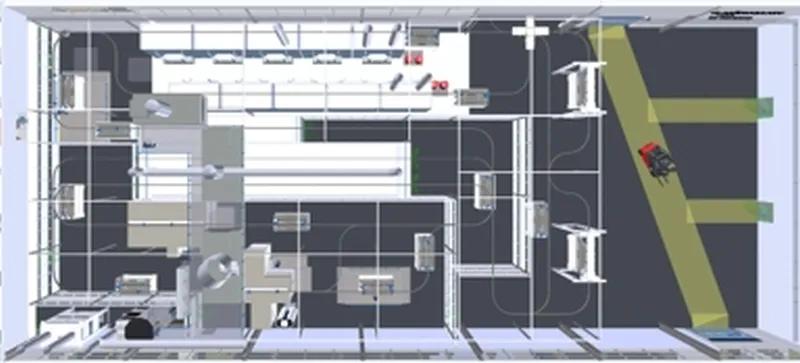

Layout design in 2D and 3D

Development of layouts in two dimensions (2D) and three dimensions (3D). Transparent visualization of set-up areas, path relationships and media routing.

Creating and evaluating a decision proposal

Creating a decision proposal with variant evaluation. Sound basis for management approvals and investment decisions.

Building permit and contract review

Preparation of the building permit and review of the contract terms. Assurance of legal requirements and reliable delivery scopes.

Advantages of our solution

- Interface clarity: Coordinated construction and plant interfaces reduce technical risks and rework.

- Planning reliability: Well-founded area dimensioning and 2D/3D layouts create a reliable basis for decision-making and implementation.

- Date stability: Consistent project management and coordinated construction phases ensure milestones in the existing building.

- Permit security: Structured preparation for planning permission speeds up procedures and increases compliance.

- Capacity increase: Expansion of the production area by 45% increases performance and supports growth.

Contact us

Interested in a customized factory planning solution for your business?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>