Reference feasibility study on a factory for an innovative retrofit product for thermal insulation of windows at Mackinac GmbH / Mackinac Technology Company

Factory feasibility study for an innovative thermal insulation retrofit product for windows at Mackinac GmbH / Mackinac Technology Company

Overview

Location: Dresden, Germany / Michigan, USA

Project year: 2019

HÖRMANN Rawema Engineering & Consulting GmbH conducted a feasibility study in 2019 for the factory to manufacture an innovative retrofit product for the thermal insulation of windows. The aim was to dimension processes, space, resources and costs in a resilient manner and to define a rough layout ready for implementation.

Project content

Data collection and structuring

Systematic collection and structuring of all relevant technical and organizational data. Clean data basis as the basis for design and evaluation.

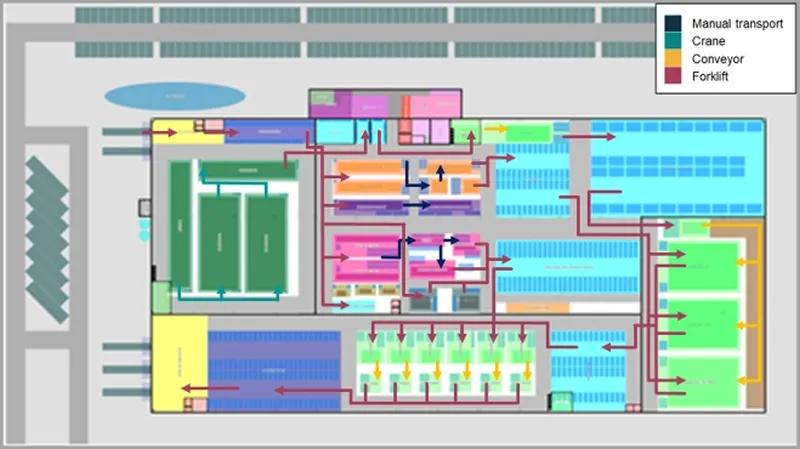

Process diagram and material flow

Creation of a process diagram and presentation of the material flows along the value chain. Clear interfaces and delivery logics for stable processes.

Space calculation

Calculation of the required production, logistics and ancillary areas. Orientation towards efficient plant structure and future expansions.

Dimensioning of machines, equipment and logistics

Dimensioning of production machines and equipment as well as logistics equipment. Efficient capacities and buffers to ensure throughput and deadlines.

Personnel requirements

Determination and dimensioning of personnel requirements per area and shift model. Transparent basis for resource planning and costs.

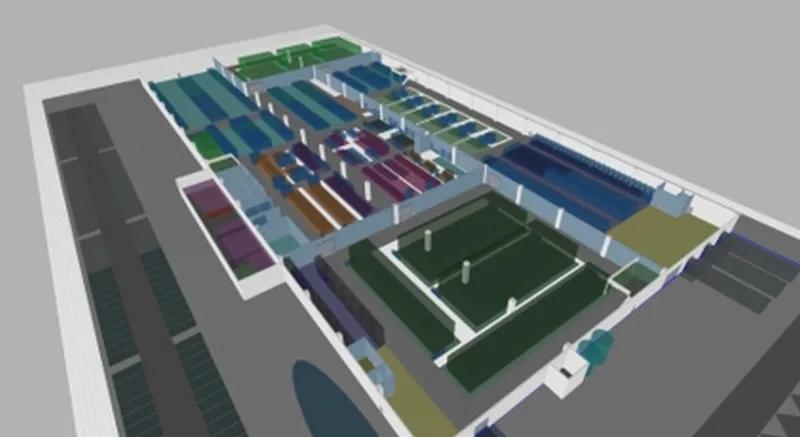

Layout design (rough layout in 2D/3D)

Development of a rough layout in 2D and 3D. Visualization of installation areas, path relationships and media connections.

Cost framework estimate

Deduction of a cost framework based on the dimensions. Decision-relevant key figures for further project phases.

Advantages of our solution

- Decision security: Well-founded dimensioning and cost framework create a clear basis for investment decisions.

- Planning certainty: Process diagrams, material flows and area calculations reduce technical and operational risks.

- Capacity clarity: Well-designed machine, logistics and personnel resources ensure performance and cycle stability.

- Transparency: 2D/3D- rough layouts make interfaces, routes and areas visible and comparable.

- Scalability: Area and resource models support subsequent expansion stages and variants.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Digitization/ Retrofit of a ball grinding machine at KRS - SEIGERT GmbH

Digitalization/retrofit of a ball grinding machine at KRS - SEIGERT GmbH

Overview

Location: Barchfeld, Thuringia, Germany

Project duration: 2017-2020; implementation since mid-2019

Production/logistics area: approx. 16.000 sqm

Research project: Plug & Control

HÖRMANN Rawema Engineering & Consulting GmbH implemented the digitalization and retrofit of a ball grinding machine for KRS - SEIGERT GmbH. The aim was to build a scalable data and visualization platform, integrate measurement data from existing sources and provide meaningful dashboards for operational control and decision support.

Project content

IT infrastructure and server architecture

Setting up the information technology (IT)- infrastructure with servers for InfluxDB (time series database), Grafana and web service. Standardized architecture as the basis for data acquisition and evaluation.

Worker terminal and measuring station integration

Provision of a worker terminal with measuring station and connection of the measuring device. Development of an active Excel-sheet for simple data acquisition and deviceäinteraction.

Data acquisition and interfaces

Recording of information from the Open Platform Communications (OPC)- server. Import of Excel-sheets with manual measurements to merge all data sources.

Business intelligence and analysis

Development of business intelligence (BI)- services in Python/Windows. Automated preparation, analysis and calculation of relevant key figures for the store floor.

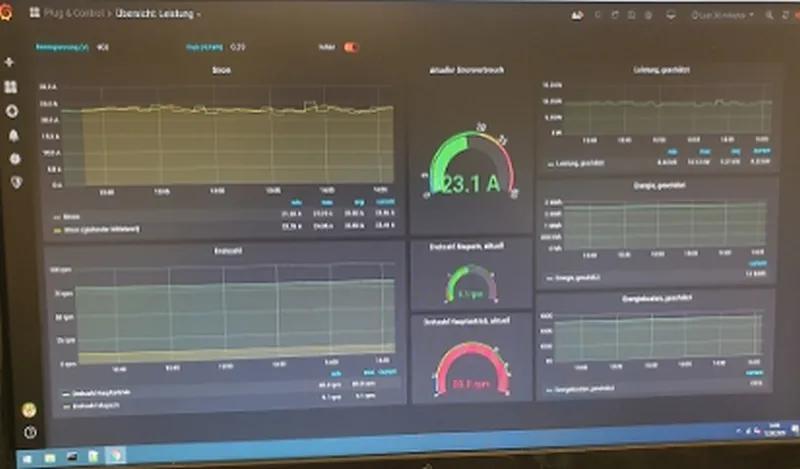

Dashboards and visualization

Design of Grafana- dashboards with access to InfluxDB. Real-time-visualization of statesänden, trends and alerts forütransparent processes.

Administration and operation

Workshops on administration and handling of the system. User empowerment and stable operating processes through clearly defined roles and routines.

Advantages of our solution

- Real-time transparency: Grafana- dashboards with InfluxDB show live and comprehensible statuses, trends and KPIs.

- Decision support: Python-based BI-services provide reliable evaluations forquick, well-founded decisions.

- Gentle retrofit: Open interfaces (OPC, Excel) modernize existing systems without in-depth interventions.

- Scalability: Standardized IT-architecture and modular services enableöpossible extensions to additional machines.

- Operational reliability: Training and clear administration concepts strengthen expertise and ensure stable, continuous operation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference process description and operating manual for indoor e-kart system at BRP - Rotax GmbH, MAX Dome in Linz

Process description and operating manual for indoor e-kart system at BRP - Rotax GmbH, MAX Dome in Linz

Overview

Location: Linz, Austria

Project duration: 2 months

Area to be covered: approx. 4.300 sqm (≈ 35 rooms, 550 objects)

HÖRMANN Rawema Engineering & Consulting GmbH successfully created the process description and operating manual for an indoor--E--Kart- system. The aim was to fully document the user experience and processes, derive construction objectives and create a reliable basis for operation and future franchise implementations.

Project content

Describing the user experience

Clear description of the intended user experience. Standardized guidelines for visitor guidance, service points and operating processes.

Complete process mapping and time evaluation

Mapping of all management, core, ancillary and franchise processes, including time evaluation. Transparent processes as the basis for control and scaling.

Identifying construction objectives

Determining general construction objectives from process and safety requirements. Orientation for planning, equipment and space organization.

Personnel matrix, room and equipment list

Creation of a detailed personnel matrix and a complete room and equipment list. Clear allocation of resources and responsibilities for operations.

Franchise derivations

Development of a schedule, safety, maintenance and cleaning concept as well as responsibilities according to RASIC (Responsible, Accountable, Support, Informed, Consulted). Practical guidelines for future franchisees.

Operations manual

Structured preparation of all content in the operations manual. Comprehensible chapter structure, clear responsibilities and robust checklists.

Advantages of our solution

- Process clarity: Standardized descriptions with time evaluation increase transparency and controllability.

- Operational maturity: Operating manual, security and service concepts ensure a reliable start and ongoing operation.

- Scalability: Franchisable derivations enable reproducible rollouts at additional locations.

- Resource transparency: Personnel matrix and room/equipment list create a clear basis for resource planning and procurement.

- Reliability of implementation: Construction objectives and scheduled measures reduce risks and accelerate decisions.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference layout planning for press line and plant expansion at HÖRMANN Automotive

Layout planning for press line and plant expansion at HÖRMANN Automotive

Overview

Location: Bánovce nad Bebravou, Slovakia

Production/logistics area: approx. 11.600 sqm

Press line: five individual presses

Scrap conveying system: Shaft and system especially for the press line

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the layout planning for a press line and the plant expansion for HÖRMANN Automotive. The aim was to design a resilient pit, scrap conveyor system and machine installation and to define a layout optimized for space and material flow for the existing hall and expansion.

Project content

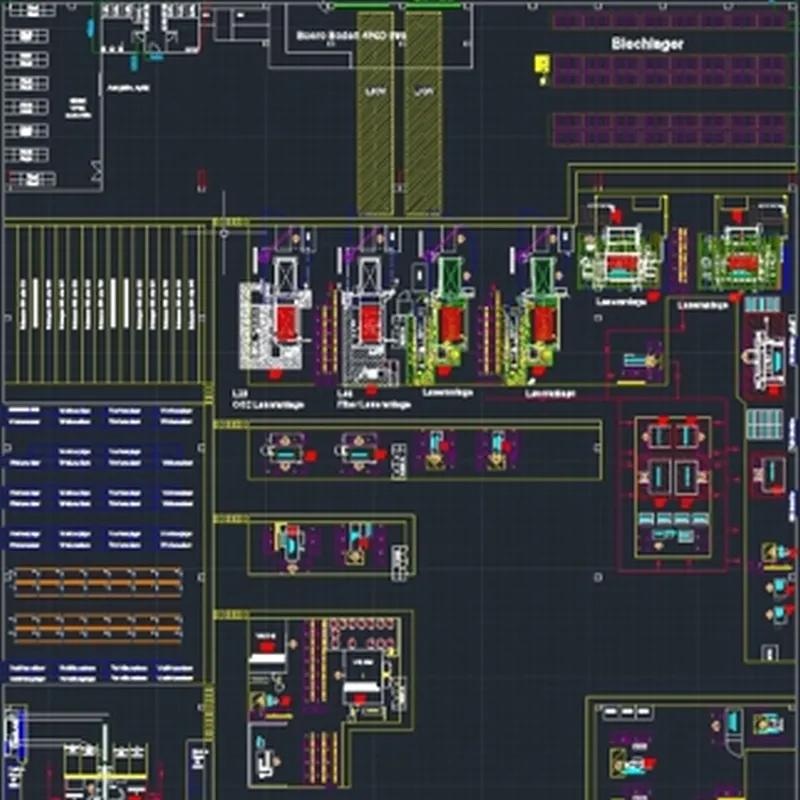

Press line pit planning

Design and planning of the press pit for five individual presses. Geometry, accesses and interfaces designed for safe assembly and maintenance.

Scrap conveyor shaft and system

Planning of a scrap conveyor shaft and the associated system specifically for the press line. Integration into layout and material flow with clear delivery logics.

Machine installation in the existing production hall

Layout planning for optimized machine installation. Short distances, clear transfer points and space-saving arrangement to stabilize processes.

Layout of hall extension (approx. 11,600 m²)

Development of the extension layout with a focus on short material flows, space efficiency and flexibility. Coordination of routes, storage areas and logistics zones.

Material flow and flexibility concept

Definition of route relationships, buffer areas and delivery zones. Focus on flexibly scalable variants and fast changeovers.

Advantages of our solution

- Space efficiency: Optimized machine set-up and expansion layout save space and increase usable floor space.

- Material flow quality: Short distances and clear delivery logics shorten throughput times and stabilize operations.

- Operational safety: Sophisticated pit planning and integrated scrap conveyor system facilitate assembly, maintenance and safe work.

- Future-proof: Flexible layouts support variant changes and gradual expansion options.

- Readiness for implementation: Precise pit and conveyor system design creates a clear basis for construction and installation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Logistics Process Planning Seat Production Mercedes G-Class (MOPF) at Magna Steyr Fahrzeugtechnik AG & Co. KG

Logistics process planning seat production Mercedes G-Class (MOPF) at Magna Steyr Fahrzeugtechnik AG & Co. KG

Overview

Location: Graz, Austria

Focus: Seat production, logistics planning, project coordination, layout planning

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the logistics process planning for the seat production of the Mercedes G- Class (MOPF) at Magna Steyr Fahrzeugtechnik AG & Co. KG. The aim was to reliably coordinate processes and interfaces, plan warehouses and sequencing in a resilient manner, create layouts and evaluate and calculate integration-capable logistics concepts - including AGVs/ AGVs -.

Project content

Project coordination between suppliers and Magna logistics

Structured coordination between suppliers and Magna's logistics departments. Clear responsibilities and information flows to ensure timely and high-quality implementation.

Process planning and internal planner coordination

Development of process planning and coordination of internal planners. Uniform premises and processes for stable material and information flows.

Warehouse planning and optimization

Design of warehouse structures and optimization of storage areas, buffers and access logics. Reduction of travel times and increase in inventory quality.

Sequencing processes and scopes

Planning of sequencing processes including scope definition. Ensuring cycle and variant-compliant delivery to seat assembly.

Layout planning

Creation of layouts with clear path relationships, transfer points and delivery zones. Transparent basis for implementation and IT-connection.

Integration variants for AGVs/ATVs

Evaluation of integration variants for automated guided vehicles (AGVs) and automated guided vehicles (AGVs). Derivation of requirements for infrastructure, IT and operations.

Evaluation and calculation of logistics concepts

Comparison and calculation of various logistics concepts. Decision preparation based on performance, costs and integration effort.

Advantages of our solution

- Interface clarity: Structured coordination of suppliers, logistics and internal planners reduces risks and speeds up coordination.

- Process stability: Clearly planned sequencing and storage processes ensure cycles and supply for seat production.

- Transparency: Clear layouts and defined premises create a comprehensible basis for implementation and IT- integration.

- Decision security: Evaluated and calculated logistics concepts enable reliable investment and operating decisions.

- Integration capability: AGV/FTF- variants with infrastructure and IT requirements facilitate scalable, future-proof operation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

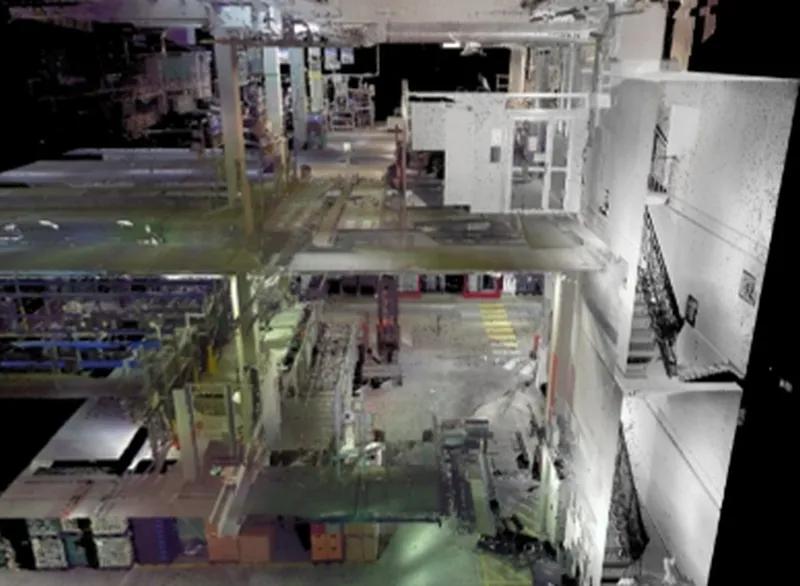

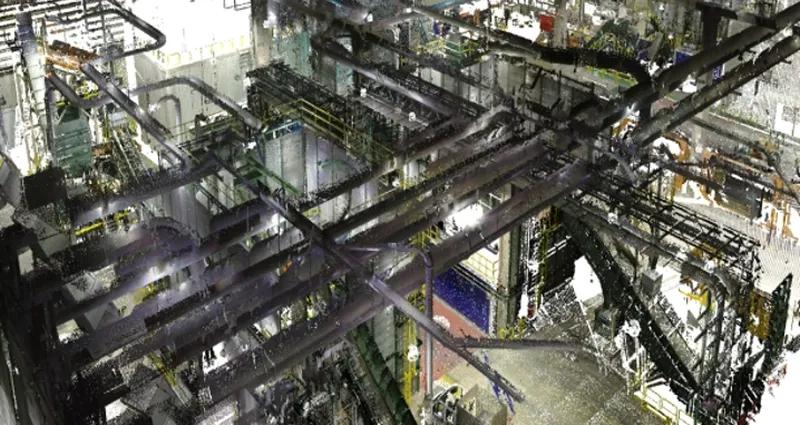

Reference 3D laser scanning for the integration of a conveyor system at ZKW Lichtsysteme GmbH

3D laser scanning for the integration of a conveyor system at ZKW Lichtsysteme GmbH

Overview

Location: Wieselburg an der Erlauf, Austria

Scanning area: approx. 10,000 m²

HÖRMANN Rawema Engineering & Consulting GmbH has successfully implemented 3D laser scanning for the integration of a conveyor system for ZKW Lichtsysteme GmbH. The aim was to precisely capture existing areas, provide views and sections from the scan data and transfer a processed point cloud to viewer-software for collision checks and measurements.

Project content

3D laser scanning production hall (partial areas)

High-resolution recording of the relevant hall zones over approx. 10,000 square meters. Basis for dimensionally accurate planning and collision-free integration of the conveyor system.

Views and sectional views

Creation of views and sectional views from the 3D- scan data. Clear visualization oföhangs, routes and fixtures.

Point cloud preparation and transfer

Preparation of the point cloud with structuring for further use. Transfer to viewer software for direct use.

Collision check between existing and planned conveyor system

Provision of data for collision check between existing and planned conveyor system. Early detection and avoidance of installation conflicts.

Measurement support

Use of the processed point cloud for reliable measurements. Ensure dimensional accuracy for detailed planning and tendering.

Advantages of our solution

- Precision: High-resolution scans provide exact as-built data for planning and integration.

- Collision-free: Viewer--compatible point clouds enableöheavy, reliable collision checks.

- Transparency: Views and sections make routes, heights and interfaces clearly visible.

- Efficiency in layoutß: Digital point clouds shorten layoutütimes and increase maötainability.

- Planning reliability: Structured dataütransfer supportsüfast decisions and reduces rework.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

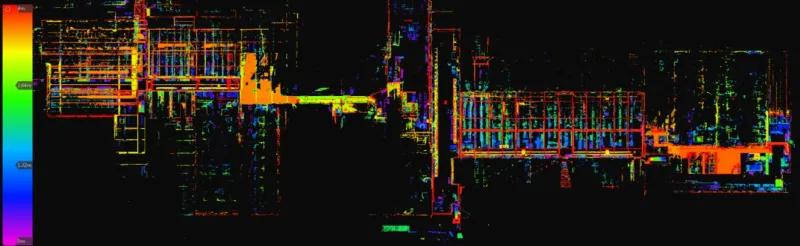

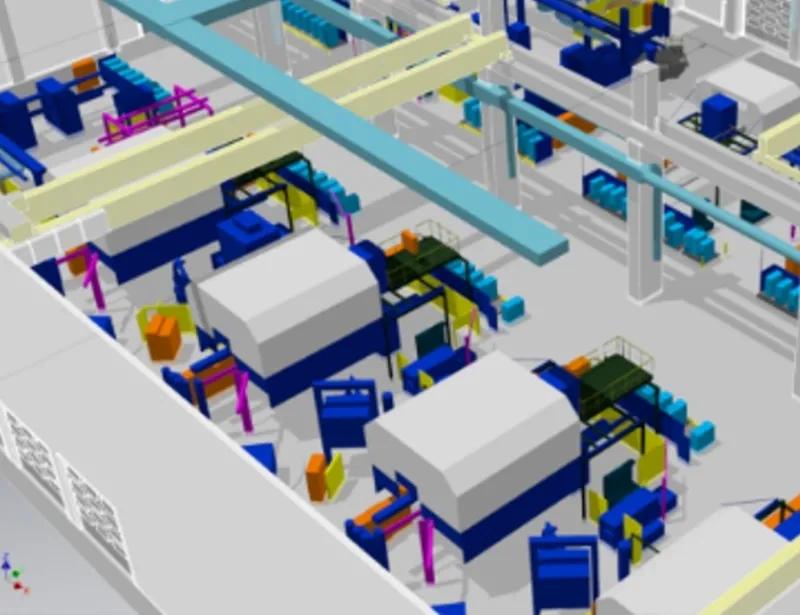

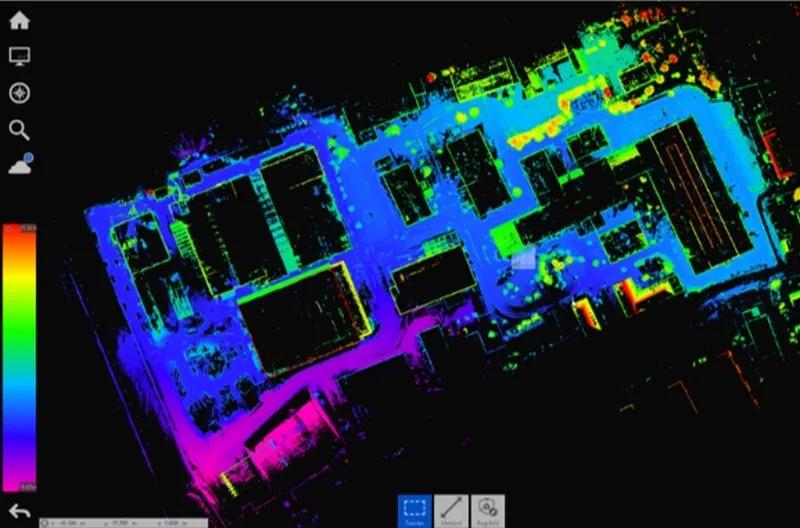

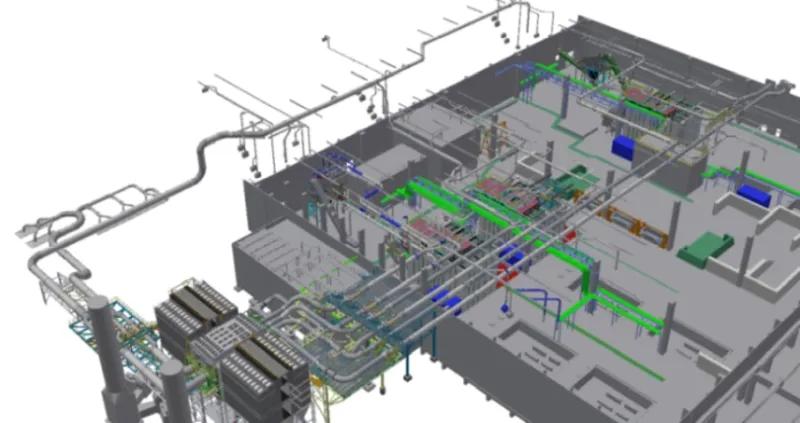

Reference 3D laser scanning of factory premises and production halls at TRIMET Automotive Holding

3D laser scanning of factory premises and production halls at TRIMET Automotive Holding

Overview

Location: Harzgerode, Saxony-Anhalt, Germany

Scanning area: approx. 100,000 m²

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the 3D laser scanning of factory premises and production halls for TRIMET Automotive Holding. The aim was to create an up-to-date 2D plant layout and provide reliable 3D models of the halls, including machinery and equipment.

Project content

3D laser scanning of the plant site and halls

High-resolution mapping of the plant site and production halls covering approx. 100,000 square meters. Precise point clouds as the basis for layout and modeling.

Current 2D plant layout

Creation of a current 2D plant layout. Clear visualization of areas, path relationships and functional areas.

3D computer-aided design (CAD)

Hall modelling Modelling of the production halls in 3D. Structured geometries for a dimensionally accurate and consistent planning view.

3D CAD models of machines and systems

Capture and modeling of machines and systems. Standardized level of detail for transparent interfaces and subsequent further planning.

Advantages of our solution

- Precision: 3D laser scans provide exact as-built data and increase the dimensional accuracy of layouts and models.

- Transparency: Up-to-date 2D factory layouts and 3D models make surfaces, paths and interfaces visible at an early stage.

- Planning reliability: Consistent data bases make decisions easier and reduce rework during implementation.

- Reusability: Structured 3D models support variant creation and downstream engineering steps.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

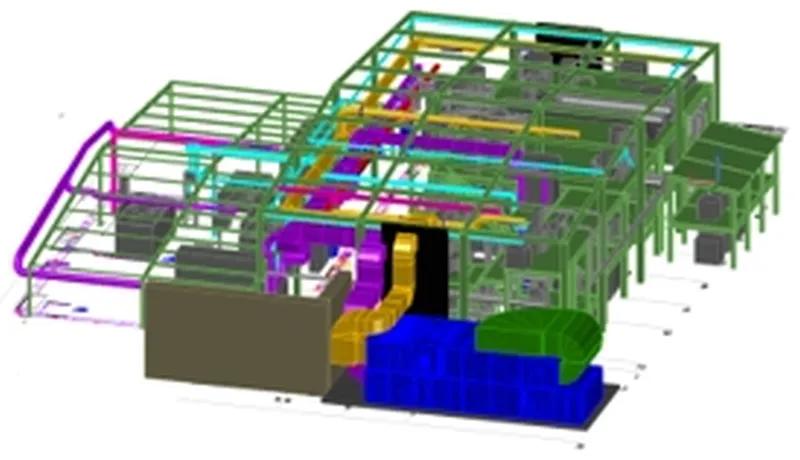

Reference planning support for the conversion of the ColdEnd at Novelis Deutschland GmbH

Planning support for the conversion of the ColdEnd at Novelis Deutschland GmbH

Overview

Location: Nachterstedt/Seeland, Germany

Project duration: 12 months

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the planning support for the conversion of the ColdEnd. The aim was to precisely design piping and steelwork layouts, to technically clarify measurement systems including explosion protection and to support the implementation by coordinating suppliers and construction sites on schedule.

Project content

3D layout planning for pipe routing and steelwork

Development of the three-dimensional (3D) layout planning for pipe routing and steelwork. Clear routes, media paths and construction points for collision-free integration.

As-built survey using 3D laser scanning

Recording of existing pipes using 3D laser scanning. Precise geometric data as a basis for planning, comparison and variant evaluation.

Technical clarification of the piping concept

Development and clarification of the technical requirements of the piping system. Ensuring functionality and interface compatibility.

Measurement systems and sensors including explosion protection

Support with the technical development of the necessary measurement systems and measurement sensors including explosion protection. Specifications for measuring points and their positioning.

2D layout planning of the piping system

Two-dimensional (2D) layout planning of the piping system including cyclone installation areas and positioning of the measuring points. Transparent representation of path relationships and connections.

Supplier management

Creation of requirement specifications and specifications as well as coordination of suppliers. Clarified interfaces and documented requirements for smooth implementation.

Construction site organization during implementation

Organization of the construction site during the implementation phase. Structured processes and clear responsibilities on site.

Advantages of our solution

- Collision-free: 2D/3D layouts and 3D laser scanning ensure consistent planning and avoid paving conflicts.

- Interface safety: Technical clarification of the piping concept and coordinated measuring systems reduce risks at media and construction interfaces.

- Explosion protection: Consideration of safety requirements increases operational safety and facilitates approvals.

- On-time implementation: Supplier management and construction site organization stabilize milestones and reduce rework.

- Transparency: Requirement specifications and specifications create a clear basis for decision-making and implementation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Extension of body shop (high-bay warehouse) at Magna Steyr Fahrzeugtechnik

Expansion of car body warehouse (high-bay warehouse) at Magna Steyr Fahrzeugtechnik

Overview

Location: Graz, Austria

Project duration: 10 months

Capacity expansion: Doubling of storage capacity

Conveyor technology: Replacement/expansion of approx. 200 elements

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the expansion of the car body high-bay warehouse at Magna Steyr Fahrzeugtechnik. The aim was to double the storage capacity, comprehensively modernize the connecting conveyor technology and reliably accompany the implementation through to commissioning (IBN).

Project content

Doubling storage capacity

Expansion of the high-bay warehouse with three new aisles and suitable storage and retrieval machines. High-performance expansion for stable supply to the assembly areas.

Replace and expand conveyor technology

Replacement and expansion of the connecting conveyor technology with approx. 200 elements. Clear interfaces and coordinated delivery logics for smooth material flows.

Concept and detailed planning

Development of robust concept and detailed planning. Definition of layout, transfer points and media connections to ensure implementation.

Tendering and contract award support

Preparation of tender documents, technical clarifications and structured bid evaluation. Contract award support to ensure quality, deadlines and costs.

Site supervision and coordination

Coordination of on-site implementation with trade interfaces. Progress monitoring and quality assurance up to functional release.

Commissioning (IBN) and acceptance preparation

Support for IBN with test plans and documentation. Preparation of acceptance with verification of performance and safety parameters.

Advantages of our solution

- Capacity increase: Three new aisles and storage and retrieval machines double the storage capacity and increase security of supply.

- Process stability: Modernized conveyor technology with around 200 elements reduces disruptions and shortens throughput times.

- On-time implementation: Structured planning, tendering and construction site coordination ensure milestones through to acceptance.

- Transparency: Precise concept and detailed planning creates clear interfaces and a reliable basis for decision-making.

- Ready for implementation: IBN support and acceptance preparation accelerate the start of production and ensure quality.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference planning / realization of a ventilation system at PCW GmbH

Planning / realization of a ventilation system at PCW GmbH

Overview

Location: Eilenburg, Saxony, Germany

Project duration: 2018 - 2020

Investment amount: over €500 thousand

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the planning and realization of a ventilation system for PCW GmbH. The aim was to precisely record the existing building, evaluate variants technically and economically and coordinate the implementation through to acceptance on schedule.

Project content

As-built survey and 3D laser scanning

Data recording of the existing building and 3D laser scanning. Precise geometric data as the basis for planning and collision avoidance.

Concept planning and variants with cost estimates

Development of technical implementation solutions in several variants with cost estimates. Decision preparation through clear service and interface descriptions.

Supply air/exhaust air/cooling system planning (3D)

Planning of supply air, exhaust air and cooling generation including 3D planning. Focus on efficient media routing and maintenance-friendly integration.

Performance parameters and design

Determination of the technical system parameters: Volume flow rate 60,000 m³/h each, cooling capacity approx. 300 kW. Dimensioning to ensure performance and energy efficiency.

Tendering and awarding

Drafting the tender documents and conducting bidder interviews. Structured tender review and award to ensure quality and costs.

Execution: coordination and monitoring

Coordination and monitoring of execution on site. Schedule, quality and interface control through to functional release.

Supplier and interface management

Active management of suppliers and technical interfaces. Ensuring smooth collaboration between all building services engineering trades.

Advantages of our solution

- Planning reliability: Precise inventory data, variant concepts and cost estimates create a reliable basis for decision-making.

- Performance: Design of supply air, exhaust air and cooling with defined parameters ensures climate quality and energy efficiency.

- On-time implementation: Structured tendering, awarding and on-site management stabilize milestones until acceptance.

- Interface clarity: Professional supplier and interface management reduces technical risks and rework.

- Transparency: Complete documentation and clear records facilitate approvals and strengthen compliance.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>