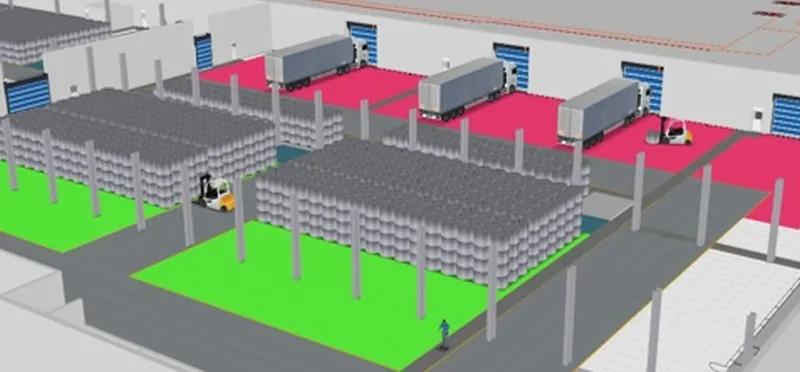

Reference Concept planning for coil storage and loading in the rolling mill at ESF Elbe-Stahlwerke Feralpi GmbH

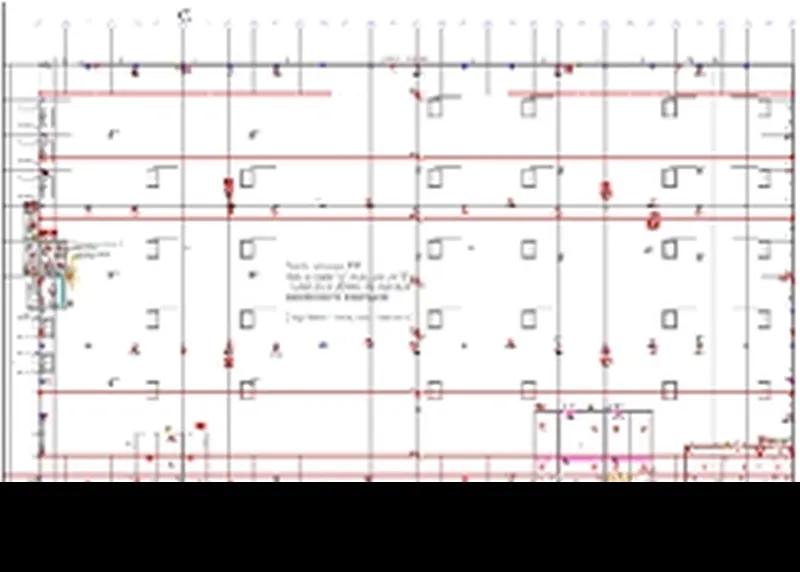

Concept planning for the coilStorage and loading in the rolling mill at ESF Elbe-Stahlwerke Feralpi GmbH

Overview

Location: Riesa, Saxony, Germany

Project duration: 2 months

Production/logistics area: 14.000 square meters

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the concept planning for coil storage and loading in the rolling mill for ESF Elbe-Stahlwerke Feralpi GmbH. The aim was to dimension storage, transport and ancillary areas as well as means of transport in a resilient manner, to structure material flows for storage, picking and loading and to determine a preferred variant based on a well-founded comparison of variants.

Project content

Data collection and framework analysis

Collection of relevant fundamentals and analysis of existing logistics flows. Clean data as a basis for dimensioning, layout and evaluation.

Space and capacity dimensioning

Dimensioning of storage, transport and ancillary areas, including parking space and buffer concepts. Derivation of capacities for a stable material flow.

Means of transport and fleet requirements

Determination of the types of means of transport and the required number. Design of areas of use and capacity utilization to ensure efficient operation.

Storage, picking and loading concepts

Development of process concepts for storage, picking and loading. Clear interfaces, transfer points and delivery logic for smooth processes.

Creating and evaluating layout variants (2D/3D)

Creating and evaluating various layout variants in two dimensions (2D) and three dimensions (3D). Examination of path relationships, parking spaces and material flow quality.

Variant comparison and preferred variant

Structured comparison of layout variants based on a catalog of criteria. Selection of the preferred variant with a reasoned decision recommendation.

Structural requirements

Evaluation of the structural requirements and interfaces. Derivation of necessary measures for implementation in existing buildings.

Advantages of our solution

- Planning reliability: Sound dimensioning and clear comparison of variants create a reliable basis for decision-making.

- Efficient material flows: Sophisticated concepts for storage, picking and loading reduce handling times and stabilize throughput.

- Transparency: 2D planning and 3D visualization make route relationships, areas and interfaces visible at an early stage.

- Scalability: Designs and layouts can be flexibly adapted to quantity and expansion stages.

- Implementability: Early clarification of construction requirements reduces risks and speeds up implementation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Simulation of shunting processes at Novelis Deutschland GmbH

Simulation of shunting processes at Novelis Deutschland GmbH

Overview

Location: Nachterstedt, Saxony-Anhalt, Germany

Project duration: 3 months

Focus: Simulation, rail logistics, shunting

HÖRMANN Rawema Engineering & Consulting GmbH successfully carried out the simulation of shunting processes for Novelis Deutschland GmbH. The aim was to realistically map shunting processes, dimension capacities and vehicle requirements and derive optimal sequences and travel times for a stable interface supply between logistics and production.

Project content

Simulation model of the shunting processes

Mapping of the shunting processes in a simulation model, taking into account the plant logistics and processes. Representation of routes, parking and transfer points.

Shunting logics under boundary conditions

Development of suitable shunting logics according to operational framework conditions. Ensuring robust processes despite restrictions and bottlenecks.

Optimal wagon sequences (inbound trains)

Determining optimal sequences for inbound trains. Reduction of transfer times and stabilization of the supply to the production areas.

Track system expansion requirements

Determination of the necessary expansion of the track systems in terms of number and length. Technical and economic assessment to safeguard investments.

Shunting vehicle numbers and utilization

Determination of the required number and utilization of shunting vehicles. Dimensioning for high-performance, cost-efficient operation.

Arrival and departure times

Determination of optimum arrival and departure times in the work cycle. Smoothing out peaks and ensuring plannable logistics windows.

Advantages of our solution

- Decision reliability: Realistic simulations and clear evaluations create a reliable basis for measures.

- Infrastructure clarity: Determined expansion requirements for track systems make investments comparable and plannable.

- Resource efficiency: Dimensioned number of vehicles and capacity utilization reduce operating costs and increase availability.

- Time stability: Optimized arrival and departure times smooth out peaks and ensure interface supply.

- Process quality: Optimal wagon sequences shorten turnaround times and stabilize the material flow to production.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

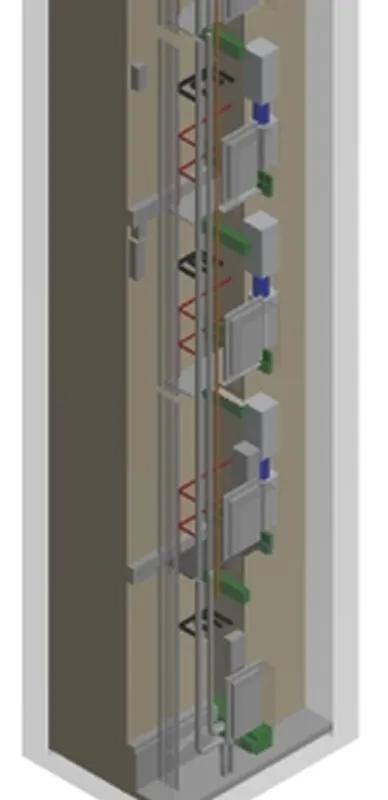

Reference 3D laser scanning and 3D modeling at Inolares GmbH & Co. KG

3D laser scanning and 3D modeling at Inolares GmbH & Co. KG

Overview

Location: Berlin, Germany

Project duration: 2 months

Special features: Smoke extraction duct, confined space, scan over several floors

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented 3D laser scanning and 3D modeling for Inolares GmbH & Co. KG. The aim was to precisely record the existing building, prepare the scan data in a reliable manner and provide an overall model as a basis for further planning of the technical building equipment (TBE).

Project content

As-built survey using 3D laser scanning

High-resolution recording of buildings and infrastructure. Documentation of critical areas such as smoke extraction ducts and multi-storey zones.

Capture methodology: terrestrial scanners and handheld

Combined use of terrestrial laser scanners and handheld devices. Ensuring complete measurement coverage despite limited space.

Scan data preparation

Registration, cleansing and structuring of the point clouds. Quality assurance and coordinate reference for consistent further use.

3D computer-aided design (CAD)

Modeling of the trades 3D modeling of buildings, ventilation, piping, electrical and technical infrastructure. Consistent level of detail for cross-trade planning.

Overall model and TGA basis

Creation of a consistent overall model as the basis for TGA planning. Clear visualization of installation areas, media routes and interfaces.

2D comparison

Check the 3D models against existing 2D documents. Ensure dimensional accuracy and completeness for downstream steps.

Advantages of our solution

- Precise data basis: Combined scanning provides complete and detailed as-built information.

- Planning transparency: The overall model provides a clear view of trades, media routing and interfaces.

- Integration capability: TGA-compliant model structure facilitates further planning and reduces rework.

- Efficiency in existing buildings: Methodology copes with cramped conditions and multi-storey areas without disrupting operations.

- Quality assurance: Structured data preparation and 2D comparison increase dimensional accuracy and reliability.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference study for production expansion & consulting on organizational development at GS Bavaria GmbH

Study for production expansion & consulting for organizational development at GS Bavaria GmbH

Overview

Location: Nuremberg, Bavaria, Germany

Project duration: 3 months

Production area (greenfield): 2.000 sqm

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented a study on production expansion and organizational development consulting for GS Bavaria GmbH. The aim was to expand the recycling process from hard metal scrap to tungsten nanopowder in a structured manner, to visualize layouts and models and to create a reliable basis for costs, deadlines and organization.

Project contents

Recycling process and target image

Definition of the process framework for the recycling of hard metal scrap to tungsten nanopowder. Derivation of a clear target image as the basis for layout, capacities and organization.

Data collection and structuring (workshops)

Collection and structuring of all relevant data in moderated workshops. Creation of a consistent data basis for planning and decision-making.

2D layouts for pilot production and greenfield

Development of a 2D layout for pilot production in the existing building and for the greenfield. Clear layout of functional, logistics and technical areas.

3D models and renderings

Creation of 3D models and rendering of 3D views. Early visualization for the evaluation of installation areas, path relationships and interfaces.

Cost framework and schedule (greenfield)

Determination of a cost framework and schedule for the greenfield. Transparent basis for budgeting and implementation steps.

Roadmap for organizational development

Development of a structured checklist/roadmap for further corporate and organizational development. Prioritized measures for roles, processes and communication.

Joint workshop

Conducting a workshop to discuss the results together. Coordination of the next steps and definition of responsibilities.

Advantages of our solution

- Holistic approach: Combines process, layout, visualization, costs and organization into a consistent basis for decision-making.

- Transparency through visualization: 2D layouts and 3D models with renderings make areas, paths and interfaces visible at an early stage.

- Planning security: Cost framework and schedule for the greenfield reduce investment and implementation risks.

- Structured development: The roadmap supports predictable organizational development with clear priorities.

- Accelerated decision-making: Workshops, consolidated data and clear documentation shorten coordination processes and increase commitment.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference 3D laser scanning and 3D modeling / 2D alignment at Flender Industriegetriebe GmbH

3D laser scanning and 3D modeling / 2D alignment at Flender Industriegetriebe GmbH

Overview

Location: Penig, Saxony, Germany

Project duration: 4 months

Production area: 14.000 sqm

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented 3D laser scanning, 3D modeling and 2D alignment for Flender Industriegetriebe GmbH. The aim was to precisely record the existing situation, create a reliable overall 3D model and ensure the data interfaces for further planning and integration.

Project content

As-built survey using 3D laser scanning

High-resolution recording of the existing plant and building condition. Basis for precise modeling and reliable planning.

Scan data preparation

Registration, cleansing and structuring of the scan data. Quality assurance and coordinate reference for consistent further use.

3D computer-aided design (CAD)

Modeling of the trades 3D modeling of production facilities, cranes, buildings and technical infrastructure. Uniform level of detail for a clear, cross-trade view.

Overall model and hall models

Creation of a consistent overall model and individual hall models. Structured visualization for planning, coordination and documentation.

Unification of machine models

Derivation of individual machine models from the overall model. Targeted provision for specific planning and coordination tasks.

2D drawing comparison

Comparison of the 3D model with as-built drawings in 2D. Ensuring consistency, dimensional accuracy and completeness.

File transfer and Siemens NX compatibility

Ensuring the compatibility of models with Siemens NX. High-performance export and seamless data exchange with downstream systems.

Advantages of our solution

- Precision: High-resolution laser scans and structured data preparation increase the accuracy of as-built models.

- Planning transparency: 3D overall and hall models create a clear basis for decision-making for all trades.

- Integration capability: Siemens NX-compatible models facilitate collaboration and further processing.

- Consistency: 2D alignment ensures dimensional accuracy and reduces rework in planning and execution.

- Reusability: Isolated machine models accelerate variant creation and change planning.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference general planning to support layout and fire protection at Erfurter Teigwaren GmbH

General planning to support layout and fire protection at Erfurter Teigwaren GmbH

Overview

Location: Erfurt, Thuringia, Germany

Project duration: 6 months

Production area: approx. 16.000 sqm

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the general planning to support the layout and fire protection for Erfurter Teigwaren GmbH. The aim was to safely and efficiently align the large-scale production of 100,000 tons per year, update plans and prepare structural and fire protection measures for approval.

Project content

Process requirements for large-scale production

Recording the specific requirements of large-scale production of pasta (100,000 t/year). Translation of the process requirements into clear layout and infrastructure specifications.

Data collection, analysis and list of measures

Systematic collection of relevant data and analysis of the current situation. Derivation of a prioritized list of measures as a basis for implementation and monitoring.

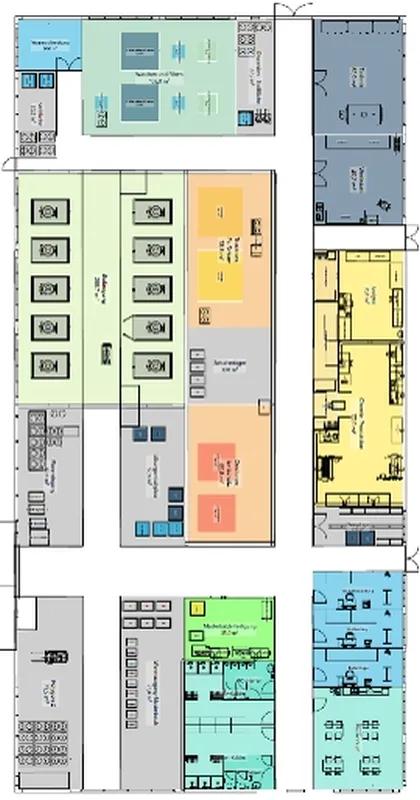

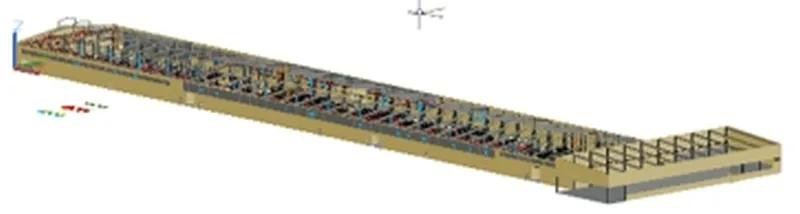

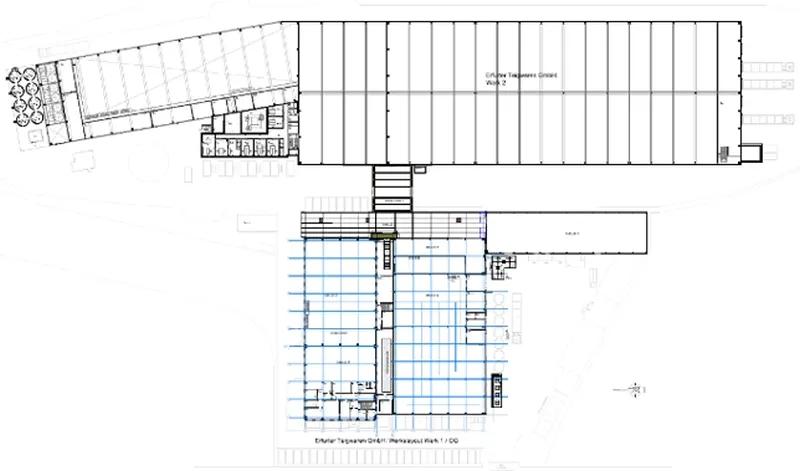

Updating floor plans and layouts (2D)

Updating the floor plans and 2D layouts of the entire building. Clear visualization of functional areas, route relationships and area allocations.

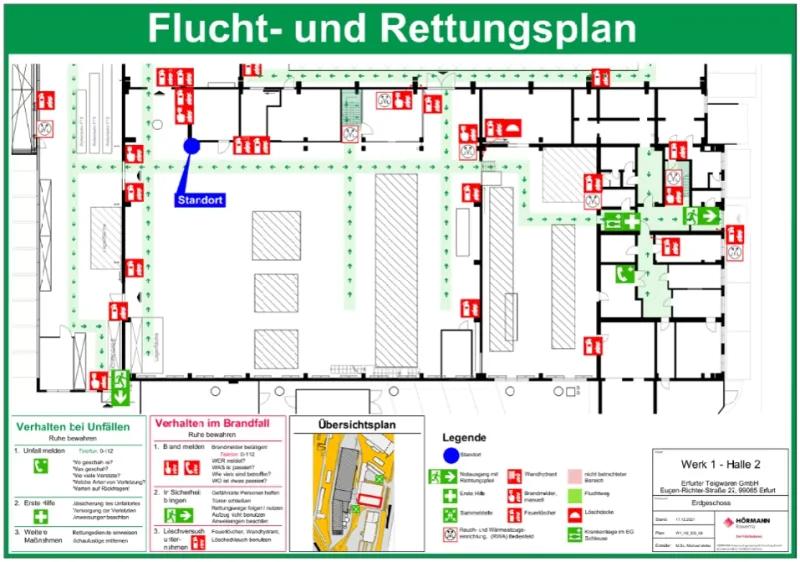

Escape and rescue plans, fire department plans

Revision of the escape and rescue plans and fire department plans. Ensuring completeness, legibility and standard-compliant presentation.

Structural and fire protection measures

Planning, tendering and implementation support for selected structural and fire protection measures. Interface coordination to minimize execution risks.

Supply air and exhaust air concepts

Revision of supply air and exhaust air concepts in the production environment. Improvement of air quality, energy efficiency and operational stability.

Authority consultations

Support with consultations with the relevant authorities. Preparation of documents and monitoring of communication through to approval.

Advantages of our solution

- Safety and compliance: Updated plans and coordinated measures meet fire safety requirements and increase operational safety.

- Transparency: Consistent 2D layouts and structured action lists create a clear basis for decision-making and implementation.

- Efficiency in the food environment: Process and layout optimizations support stable processes and high quality in large-scale production.

- Reliable implementation: Planning, tendering and implementation support reduce time, cost and interface risks.

- Clarity with authorities: Professional support in coordinating with authorities speeds up approvals and reduces rework.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference General planning of new production hall at YINLUN SETRAB POLAND Sp. z o.o.

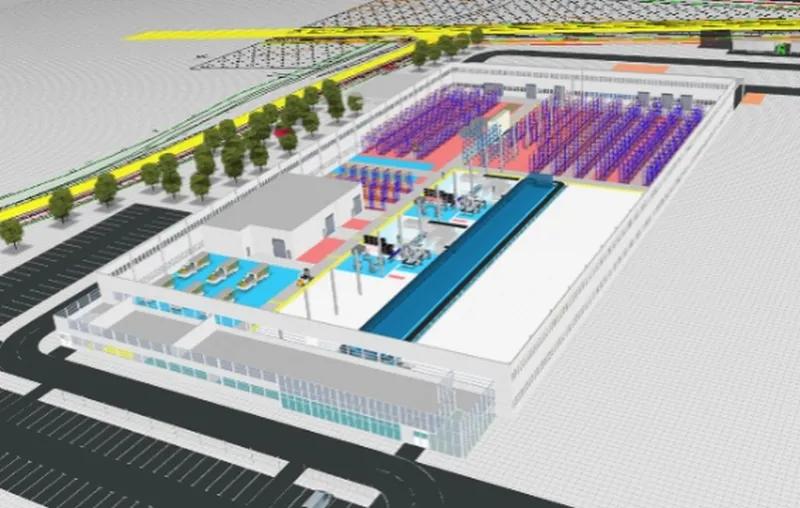

General planning for new production hall at YINLUN SETRAB POLAND Sp. z o.o.

Overview

Location: Karlino, Poland

Project duration: 2020-2023

Production area: 10.000 sqm

Investment sum: €11 million

HÖRMANN Rawema Engineering & Consulting GmbH has successfully implemented the general planning for the construction of a new production hall for YINLUN SETRAB POLAND Sp. z o.o.. The aim was to design space-efficient processes, provide documents ready for approval and enable smooth, punctual implementation.

Project content

Space dimensioning

Determination of space requirements for production, logistics and technology. Focus on efficient plant structure and future-proof scaling.

Logistics planning

Conception of internal material flows, route relationships and buffer areas. Ensuring stable processes from goods receipt to dispatch.

Layout design in 2D/3D

Creation of a site-specific layout in two dimensions (2D) and three dimensions (3D). Transparent visualization of installation areas, media connections and functional areas.

Interface clarification and management

Coordination of all trades with clear interfaces. Early clarification of technical and structural dependencies to minimize risk.

Approval planning (Federal Immission Control Act (BImSchG) and construction)

Drafting of the necessary approval documents for BImSchG and construction. Preparation of the application process and coordination with the relevant authorities.

Construction and technical building equipment (TGA)

Planning service phases (LP) 1-7 according to the Fee Structure for Architects and Engineers (HOAI) Continuous planning of construction and TGA over the LP 1-7 incl. project management. Structured preparation for execution with reliable documents.

Advantages of our solution

- Clear interfaces: Integrated management of all trades reduces technical risks and speeds up implementation.

- Planning reliability: Approvable documents (BImSchG and construction) and HOAI-compliant LP 1-7 ensure reliable decisions.

- Efficient plant structure: Space and logistics planning optimizes material flows and supports efficient production.

- Transparency: 2D/3D layouts create a clear view of installation areas, media and functional areas.

- Investment security: Stringent general planning supports the plannable realization within the scope of €11 million.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

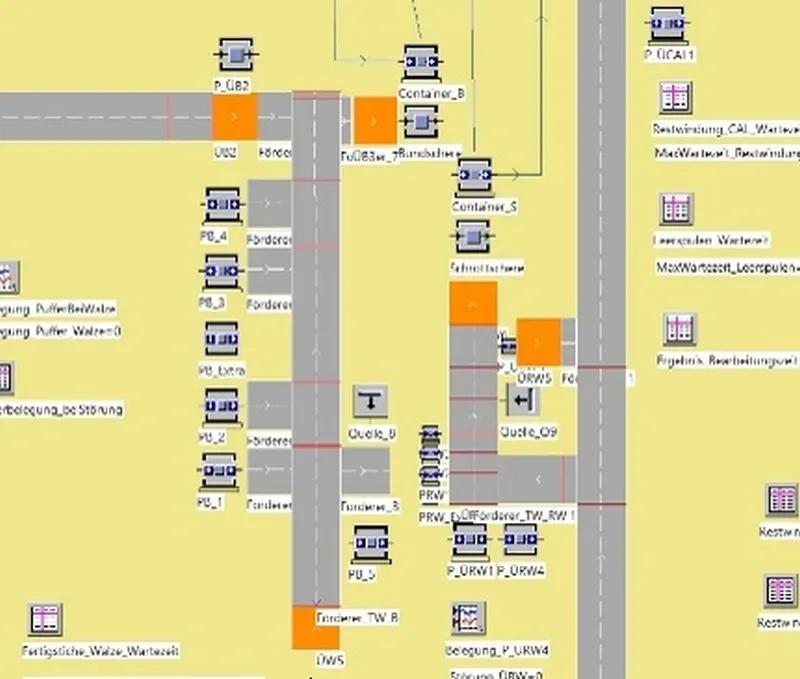

Reference Conceptual design of an automatic coil & scrap handling system at Novelis Deutschland GmbH - Ohle site

Conception of an automatic coil & scrap handling system at Novelis Deutschland GmbH - Ohle site

Overview

Location: Ohle (Plettenberg), North Rhine-Westphalia, Germany

Project duration: May 2023 - January 2024

Production area: approx. 8.000 sqm

Scope of planning: approx. 150 T€

HÖRMANN Rawema Engineering & Consulting GmbH has successfully implemented the conceptual design of an automatic coil & scrap handling system for Novelis Deutschland GmbH - Ohle site. The project aimed to automate material flows, design the new system technology functionally and safely and verify the performance requirements using simulation.

Project content

Automatic conveyor systems for coils and scrap

Conception of automatic conveyor systems for coils, residual windings and empty coils as well as scrap containers. Integration of two coil shears into the overall system with defined transfer points and interfaces.

3D concept planning of the system technology

Development of 3D concept planning including conceptual modeling of the new technology. Visualization of installation areas, path relationships and media connections to ensure integration.

Function and performance simulation

Simulation of the system technology to verify the required functionalities and performance parameters. Evaluation of throughput, availability and bottlenecks as a basis for the design.

Overall safety concept

Conception of an overarching safety concept for systems, handovers and operating processes. Consideration of normative requirements and operational safety measures.

Designing construction measures

Determination of the necessary construction measures for foundations, supporting structure and infrastructure. Clarification of interfaces between technology, construction and operation.

Functional tender

Development of functional tender documents for plant technology and construction measures. Precise service descriptions for structured bid solicitation and evaluation

Advantages of our solution

- Verified performance: Simulations confirm functionality and performance parameters before implementation.

- Interface clarity: 3D concept planning makes transfer points, installation areas and media connections transparent.

- Operational safety: A holistic safety concept increases protection and availability during operation.

- Readiness for implementation: Functional tenders accelerate procurement and ensure comparability of offers.

- Efficient material flows: Sophisticated conveyor concepts for coils and scrap stabilize throughput and reduce handling costs.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

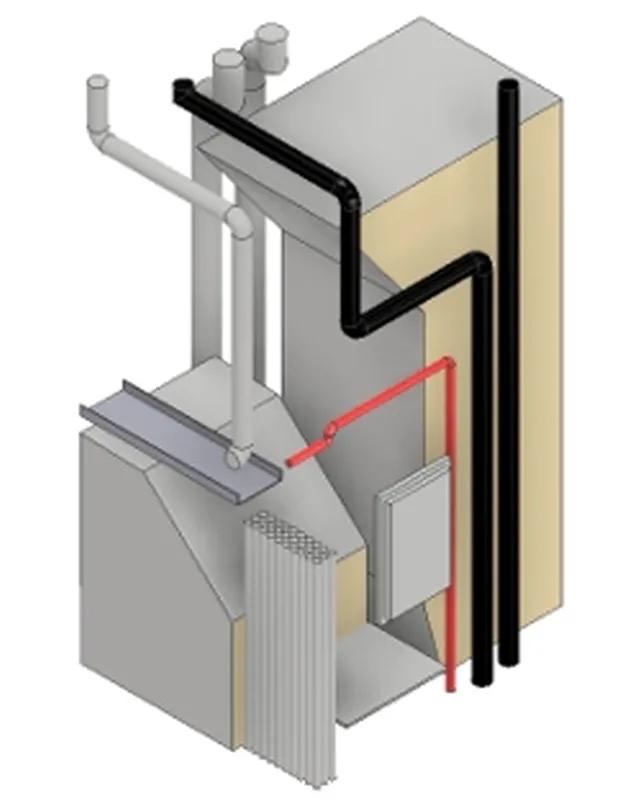

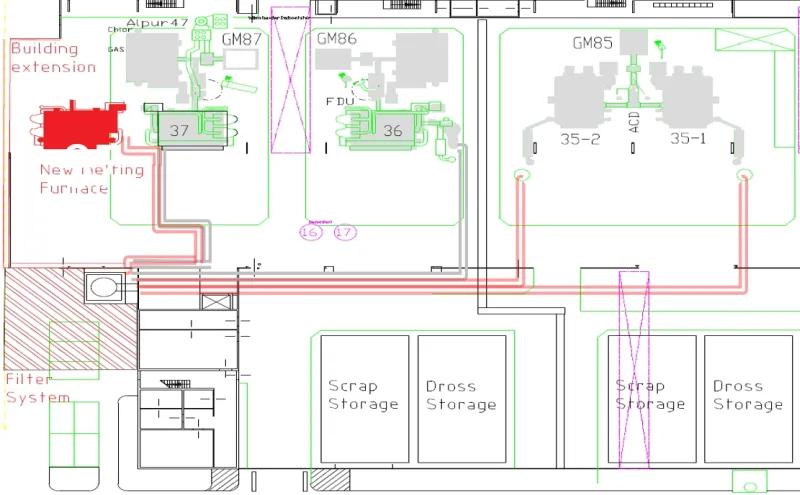

Reference Planning support for casting volume expansion incl. new exhaust air system at Constellium Singen

Planning support for casting volume expansion incl. new exhaust air system at Constellium Singen

Overview

Location: Singen, Baden-Württemberg, Germany

Project duration: 2022-2023

Investment amount: 12 m. €

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the planning support for the expansion of the casting volume including a new exhaust air system for Constellium Singen. The project aimed to clarify technical and structural interfaces, prepare for implementation and secure budget and supplier decisions.

Project content

Specific specifications for melting furnace and exhaust air system

Creation of precise specifications as a basis for inquiries to potential suppliers. Clear service descriptions and interfaces ensure comparability and quality.

Layout and infrastructure planning

Development of a site-specific layout and technical infrastructure. Consideration of media connections, pathways and set-up areas for smooth operation.

Preliminary planning of the hall extension

Preliminary planning of the structural extension with definition of the structural requirements. Coordination of areas, supporting structure and approval requirements.

Budget planning

Resilient budget planning within a framework of €12 million. Transparent cost breakdown to safeguard investment decisions.

Supplier management

Structured inquiry and quotation processes. Coordination of suppliers, clarification of interfaces and evaluation of offers.

Risk management

Identification of technical, scheduling and financial risks. Derivation of measures to minimize and safeguard implementation.

Advantages of our solution

- Interface clarity: Integrated layout, infrastructure and preliminary construction planning clarifies media, areas and processes.

- Investment security: Transparent budget planning and precise specifications make costs and scope of services comparable.

- Implementation capability: Clearly prepared tenders and professional supplier management accelerate procurement and implementation.

- Risk transparency: Early risk analysis with specific measures reduces technical and time-related uncertainties.

- Quality assurance: Coordinated requirements ensure the functionality of the melting furnace and exhaust air system.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference concept planning for the use of an AGV in the assembly area at Clarios GmbH & Co.KG

Concept planning for the use of an AGV in the assembly area at Clarios GmbH & Co.KG

Overview

Overview Location: Zwickau, Saxony, Germany

Project duration: 4 months

Production/logistics area: approx. 10.000 sqm

Investment sum: over €3 million

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the concept planning for the use of an automated guided vehicle system (AGV) in the assembly area for Clarios GmbH & Co.KG. The project aimed to automate internal logistics, stabilize material flows and sustainably increase efficiency.

Project content

Data collection and framework analysis

Collection of the relevant basics and detailed analysis of the logistics flows. Clean data as a basis for further design and evaluation.

Material flow visualization with visTABLE

Visualization of material flow relationships using visTABLE in 2D/3D. Transparent representation of path relationships, transfer points and buffer areas.

Implementation variants

Development of several implementation variants for AGV use. Evaluation according to performance, integration effort, scalability and operational reliability.

Dimensioning the AGV

Determination of the number, areas of application and utilization of the automated guided vehicle system (AGV). Derivation of the required vehicle configurations and routes for stable operation.

Supplier coordination

Coordination with potential suppliers on technical solutions, interfaces and service concepts. Targeted preparation for bid and selection processes.

Rough cost estimate for systems and logistics

Rough cost estimate for AGVs, infrastructure and logistics processes. Link to milestones for reliable decision-making and scheduling.

Advantages of our solution

- Increased efficiency: Automated material flows reduce travel times and stabilize throughput in assembly.

- Transparency: visTABLE visualizations provide clarity about routes, transfers and buffer concepts.

- Planning reliability: Variant comparison and AGV dimensioning minimize technical and operational risks.

- Scalability: Modular system structure enables gradual expansion and adaptation to production volumes.

- Investment clarity: Rough cost estimate tailored to an investment framework of over €3 million supports well-founded decisions.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>