Reference production planning bogie at Siemens

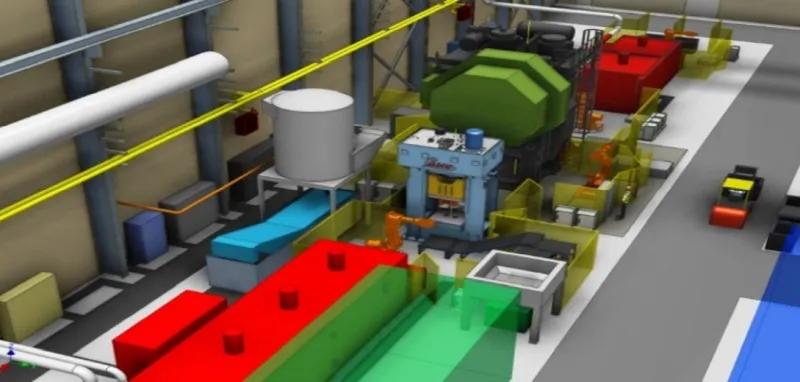

Bogie production planning at Siemens

Overview

Location: Graz, Austria

Production area: approx. 9,600 square meters

Focal points: Production, welding processes, material handling

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the production planning of a bogie for Siemens. The aim was to design fixtures and loading in a variant-capable manner, optimize material flows and layout and provide a reliable basis for investment, time and personnel.

Project content

Fixture concepts (4 variants)

Concepts for fixtures in four variants. Evaluation according to stability, set-up effort and integration capability in the process.

Automatic vs. manual feeding

Comparison of automatic and manual feeding in terms of performance, ergonomics and cost-effectiveness. Derivation of the preferred solution for series use.

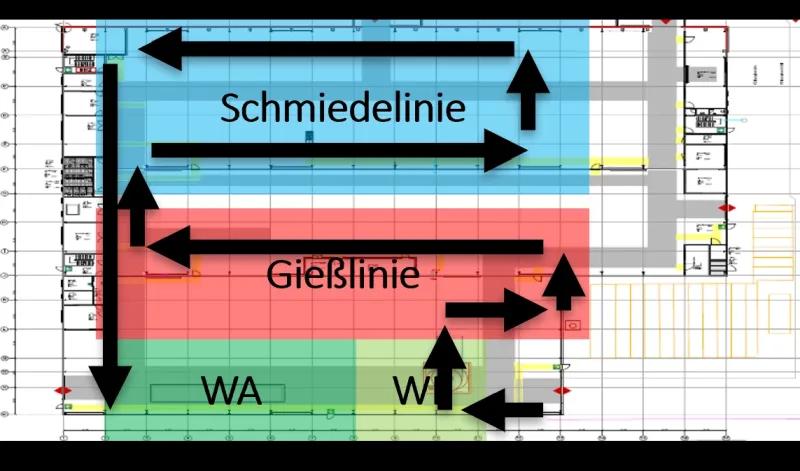

Hall layout and material positioning

Hall layout for chassis production and dimensioning of the material positioning areas. Clear path relationships and buffer concepts for stable processes.

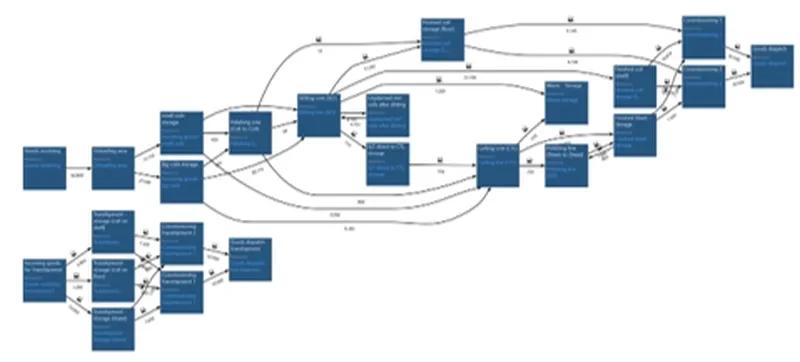

Process sequences for long beams and center connectors

Creation of process flow diagrams for long beams and center connectors. Transparent sequence and transfer points as a basis for cycle design and control.

Economics and investment framework

Economics analysis and summary of the necessary equipment and investment volume. Comparison of the variants with cost and benefit assessment.

Proposal for award of contract

Deduction of a proposal for award of contract based on technical criteria and economic efficiency. Preparation of a structured tendering and decision-making process.

Time and manpower requirements

Determination of production time and manpower requirements. Dimensioning for high-performance, cost-efficient operation.

Advantages of our solution

- Decision certainty: Variant comparison, profitability assessment and contract award proposal create a clear basis for procurement and implementation.

- Increased efficiency: Optimized hall layout, material arrangement and suitable loading shorten throughput and set-up times.

- Clarity of investment: Transparent compilation of the equipment and investment volume facilitates budgeting and prioritization.

- Process transparency: Process flow charts make sequences, handovers and cycles traceable and controllable.

- Capacity planning: Precise time and personnel determination supports a resilient, scalable production organization.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference MTM analyses final assembly and production at Liebherr-Hausgeräte Lienz GmbH

MTM analyses of final assembly and production at Liebherr-Hausgeräte Lienz GmbH

Overview

Location: Lienz, Tyrol, Austria

Project duration: 2020-2021

Areas: Final assembly, final assembly islands

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented MTM analyses in final assembly and production for Liebherr-Hausgeräte Lienz GmbH. The aim was to document workflows transparently, evaluate them in terms of time management and provide standardized process modules for variant planning and optimization.

Project content

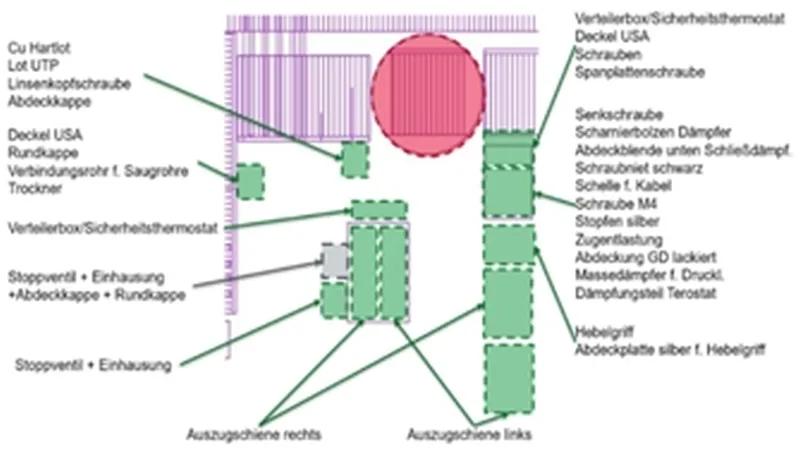

Data acquisition in assembly areas

Description of the work sequences with the parts to be assembled, documentation of the individual work steps and creation of a workstation overview. Consistent data basis for time management evaluation.

MTM time determination and TiCon documentation

Detailed determination and listing of times according to Methods-Time Measurement - Universal Analysis System (MTM-UAS) in TiCon. Complete assignment of times to work steps for comparability and evaluation.

Product-neutral MTM process modules

Development of product-neutral MTM process modules. Reusable standards for rapid evaluation of new or changed processes.

Variant creation based on reference analysis

Generation of product variants based on the reference analysis of type representatives. Structured transfer of time and process data to variants.

Optimization approaches

Identification of possible optimization approaches in workflow, ergonomics and cycle design. Prioritized measures as a basis for implementation and monitoring.

Advantages of our solution

- Time transparency: MTM UAS times in TiCon make processes measurable and comparable.

- Standardization: Product-neutral process modules accelerate the evaluation and rollout of new variants.

- Variant clarity: Reference analyses enable reliable time and process transfers to product variants.

- Efficiency potential: Concrete optimization approaches support cycle stability and ergonomic improvements.

- Planning fundamentals: Clean data collection and structured documentation provide a reliable basis for decisions.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference digitization consulting, 3D laser scanning, BIM at BRP Rotax GmbH & Co KG

Digitization consulting, 3D laser scanning, BIM at BRP Rotax GmbH & Co KG

Overview

Location: Gunskirchen, Upper Austria, Austria

Project duration: 4 months

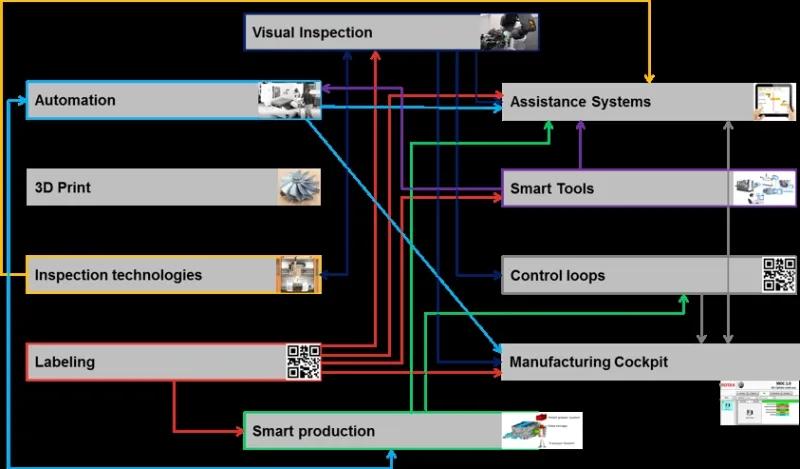

Focus: Digitalization, Smart Factory, Building Information Modeling (BIM), 3D-Modelling

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented digitalization consulting, 3D laser scanning and BIM-support for BRP Rotax GmbH & Co KG. The aim was to prepare digital initiatives in a structured manner, involve stakeholders across all management levels and create a reliable basis for planning using precise as-built data and layout models.

Project content

Sequence of events

Creation of a detailed sequence of events as a process specification for digital measures. Clear responsibilities and milestones for plannable implementation.

Media partner coordination

Coordination of media partners for coordinated communication and technical provision. Ensuring consistent content and formats for internal and external stakeholders.

Potential analysis of planned measures

Initial potential analysis of the planned digitalization measures. Evaluation of benefits, costs and feasibility as a basis for prioritization.

Assessment workshops

Planning of assessment workshops with relevant stakeholders. Structured agenda and target definition for resilient results.

Script for media implementation

Creation of a script for the media implementation of digital initiatives. Consistent messages and visualizations for decision-makers and employees.

Questionnaire for management levels

Development of a questionnaire to integrate different management levels into digital change processes. Recording of requirements, expectations and hurdles.

3D laser scanning and layout modeling

Inventory using 3D laser scanning and layout modeling. Precise data basis to support Smart-Factory-initiatives and BIM-processes.

Advantages of our solution

- Decision-making basis: Sequence of events, workshops and potential analysis create a reliable basis for prioritization and implementation.

- Stakeholder alignment: Script and questionnaire ensure a common understanding and promote active participation across all levels.

- Data and model quality: 3D- laser scans and layout models increase accuracy and predictability forü digital transformation projects.

- Speed of implementation: Coordinated media partners and clear formats speed up communication, preparation and implementation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Planning / realization of new coating plant and hall reconstruction at HÖRMANN Automotive Eislingen

Planning / realization of new coating plant and hall reconstruction at HÖRMANN Automotive Eislingen

Overview

Location: Ebersbach, Baden-Württemberg, Germany

Project duration: 21 months

Expansion of production area: 45 %

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the planning and realization of a new coating plant as well as the hall reconstruction for HÖRMANN Automotive Eislingen. The aim was to clarify interfaces, manage refurbishment measures across the entire site and design areas and layouts in a resilient manner.

Project content

Project management

Continuous project management across all phases. Clearly defined processes and responsibilities ensure deadlines, quality and budget.

Clarification of interfaces between construction trades and technological equipment

Structured clarification of interfaces between construction trades and technological equipment. Minimization of technical risks and smooth integration of the plant.

Refurbishment measures for the entire site

Planning and implementation of the refurbishment measures for the entire site. Coordination of the construction phases to reduce disruptions to ongoing operations.

Space dimensioning

Determination of space requirements for production, logistics and infrastructure. Orientation towards efficient plant structure and future expansions.

Layout design in 2D and 3D

Development of layouts in two dimensions (2D) and three dimensions (3D). Transparent visualization of set-up areas, path relationships and media routing.

Creating and evaluating a decision proposal

Creating a decision proposal with variant evaluation. Sound basis for management approvals and investment decisions.

Building permit and contract review

Preparation of the building permit and review of the contract terms. Assurance of legal requirements and reliable delivery scopes.

Advantages of our solution

- Interface clarity: Coordinated construction and plant interfaces reduce technical risks and rework.

- Planning reliability: Well-founded area dimensioning and 2D/3D layouts create a reliable basis for decision-making and implementation.

- Date stability: Consistent project management and coordinated construction phases ensure milestones in the existing building.

- Permit security: Structured preparation for planning permission speeds up procedures and increases compliance.

- Capacity increase: Expansion of the production area by 45% increases performance and supports growth.

Contact us

Interested in a customized factory planning solution for your business?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference relocation planning and coordination of overall production at HÖRMANN Automotive Penzberg and Slovakia

Relocation planning and coordination of overall production at HÖRMANN Automotive Penzberg and Slovakia

Overview

Location: Penzberg, Bavaria, Germany / Slovakia

Project duration: 17 months + follow-up projects

Project costs: approx. 74.3 million €

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the relocation planning and coordination of the entire production from HÖRMANN Automotive Penzberg to HÖRMANN Automotive Slovakia. The aim was to coordinate plant and equipment relocations with OEM end customers, secure deadlines and make it possible to plan the production start-up at the target location.

Project content

Relocation of entire production scopes

Planning and management of the transfer of mechanical production and assembly from Penzberg to Slovakia. Structured sequencing to ensure quality and deadlines.

Relocation packages

Support and planning Definition, prioritization and development of relocation packages. Clear content, milestones and resources for each package.

Relocation of plant and equipment

Coordination and agreement of the necessary relocation of plant and equipment. Interface clarification of dismantling, transportation, assembly and commissioning.

OEM end customer coordination

Coordination with the original equipment manufacturers (OEMs) involved - MAN, Daimler, Scania, John Deere and Meiller. Clarification of requirements, handover points and deadlines.

Scheduling and status tracking

Scheduling and planning across all packages. Ongoing tracking of the relocation status and assurance of plan fulfillment.

Information preparation and reporting

Processing of decision-relevant information. Regular reporting to stakeholders with transparent key figures.

Advantages of our solution

- End-to-end control: Consistent planning and coordination from dismantling to commissioning reduces risks and downtime.

- Timeline clarity: Binding scheduling and status tracking ensure milestones over 17 months and in follow-up projects.

- Interface coordination: Coordinated system, equipment and OEM interfaces increase quality and reliability.

- Transparency: Structured information preparation and reporting create traceability and quick decisions.

- Investment security: A clear overview of project costs of around €74.3 million supports budget adherence and prioritization.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference installation of intermediate level and new engine sequencer, Plant 3/Building 20 at Porsche AG

Installation of intermediate level and new construction of engine sequencer, Plant 3/Building 20 at Porsche AG

Overview

Location: Zuffenhausen, Baden-Württemberg, Germany

Project duration: 2017-2018

Construction costs: approx. 15 million euros

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the installation of an intermediate level and the construction of a new engine sequencer in Plant 3/Building 20 for Porsche AG. The aim was to implement the measures on schedule during ongoing operations, minimize disruptions and prepare acceptances in a plannable manner.

Project content

General planning

Consistent general planning across all relevant trades. Clear principles and processes as the basis for implementation in existing buildings.

Dismantling of existing facilities

Planning and implementation of selective dismantling. Ensuring occupational safety and adherence to deadlines.

Scheduling and coordination ("non-operating time")

Fine scheduling and coordination of the conversion measures in the "non-operating time" corridors. Minimization of production interruptions through coordinated time windows.

Compact construction during operation

Design and implementation in compact construction. Minimal disruption to adjacent, ongoing production.

Realization in several construction phases

Structured construction phases for gradual implementation. Ensuring access, safety and quality for each section.

Construction supervision and coordination, supplier and start-up management

Continuous construction supervision and coordination of trades. Control of suppliers and start-up management up to functional release.

Acceptance

Preparation and execution of acceptance tests. Proof of the required performance and safety parameters.

Advantages of our solution

- Deadline reliability: Detailed planning and coordination in "non-operating time" ensure milestones during ongoing operation.

- Operational stability: Compact construction methods and section-by-section implementation minimize disruptions to production.

- Quality assurance: Continuous construction monitoring and clear acceptance criteria increase execution quality.

- Transparency: General planning and coordinated processes create clear responsibilities and a basis for decision-making.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Redesign of the exhaust air system of a production area at Novelis Sheet Ingot GmbH

Rescheduling of the exhaust air system of a production area at Novelis Sheet Ingot GmbH

Overview

Location: Nachterstedt plant, Saxony-Anhalt, Germany

Project duration: 12 months

Focus: Inventory, 3D scan, piping redesign, system planning, project management

HÖRMANN Rawema Engineering & Consulting GmbH implemented the redesign of the exhaust air system of a production area at the Nachterstedt plant with the aim of measurably improving flow behavior, safety functions and reliability and ensuring implementation through to final acceptance.

Project content

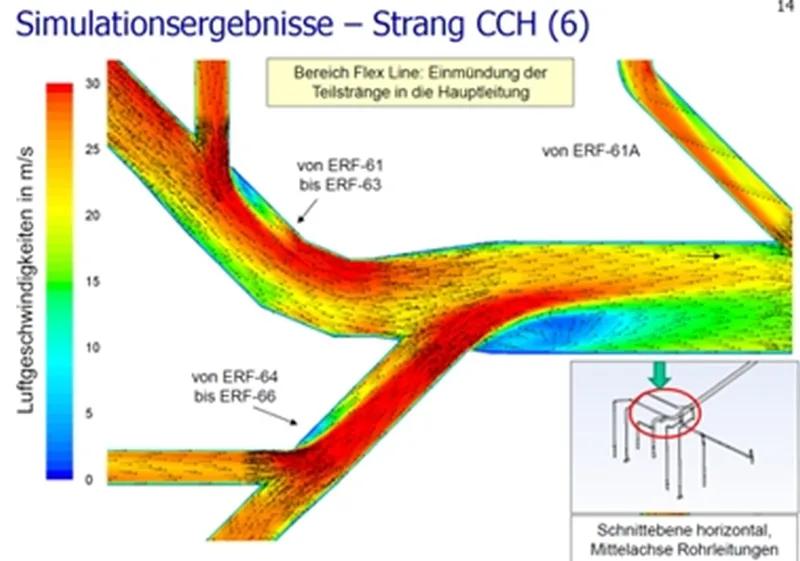

Exhaust air system analysis and improvements

Analysis of the existing exhaust air system and derivation of targeted improvements in terms of flow behavior, safety functions and reliability. Reliable basis for replanning and implementation.

3D laser scan of existing ducts

Inventory of the ductwork using 3D laser scanning. Precise recording of geometries and interfaces as a basis for planning and collision checks.

CFD flow calculation

Calculation of flow resistances using computational fluid dynamics (CFD). Evaluation of pressure losses and power reserves for designing the new pipe routing.

3D pipeline redesign

Redesign of the pipeline routing in 3D. Optimized routes, cross-sections and installations to improve throughput and operational reliability.

Specification of measures and supplier selection

Specification of the conversion measures with clear descriptions of services and interfaces. Structured supplier selection and support through to commissioning.

On-site planning and monitoring

Planning and monitoring of the conversion measures on site. Schedule, quality and interface coordination through to functional approval.

Final acceptance and documentation

Execution of the final acceptance with proof of performance. Complete documentation as a basis for operation, maintenance and subsequent adjustments.

Advantages of our solution

- Flow efficiency: CFD-supported design reduces flow resistance and stabilizes exhaust air performance.

- Operational safety: Improved safety functions and quality-assured implementation increase reliability and availability.

- Transparency: 3D scanning and 3D replanning make pipe routing, installations and interfaces clearly comprehensible.

- On-time implementation: Precise specification of measures, supplier management and on-site monitoring reduce risks and rework.

- Documentation clarity: Final acceptance and complete documentation provide evidence and auditability for operation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference New construction of an unpacking and used sand processing plant for casting/sand separation for large castings at Caterpillar Castings Kiel GmbH

New construction of an unpacking and used sand processing plant for casting/sand separation for large castings at Caterpillar Castings Kiel GmbH

Overview

Location: Kiel, Schleswig-Holstein, Germany

Project duration: 8 months

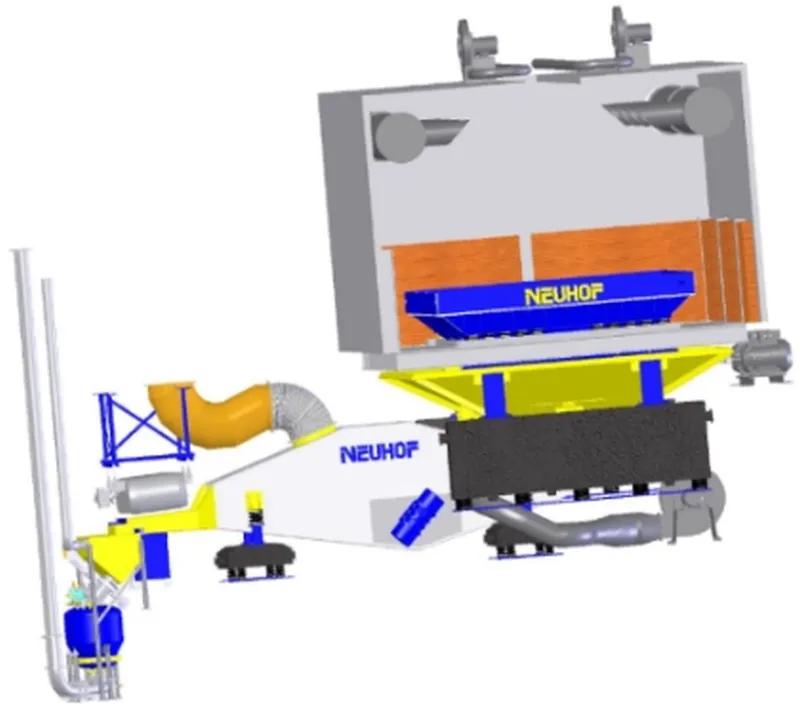

Scope of plant: Unpacking and used sand processing plant for casting/sand separation for large castings

HÖRMANN Rawema Engineering & Consulting GmbH successfully supported the construction of a new unpacking and used sand processing plant for casting/sand separation for large castings. The aim was to ensure that procurement, implementation and commissioning were technically and economically sound and that the required performance parameters were demonstrably achieved.

Project content

Tender documents (specifications and functional specifications)

Development of precise specifications and functional specifications as the basis for the supplier inquiries. Clear service and interface descriptions ensure comparability.

Solicitation of offers and supplier management

Structured solicitation of offers with technical and commercial comparison. Management of supplier communication and derivation of a reliable selection.

Supply and service contract

Support in drawing up a supply and service contract. Assurance of deadlines, quality and warranty requirements.

Pre-acceptance at the supplier

Conducting pre-acceptance tests to validate functionalities. Early validation of key performance features prior to assembly.

Assembly coordination and monitoring

Coordination of assembly processes and monitoring of execution. Clarification of interfaces and quality assurance up to functional release.

Commissioning, monitoring and proof of performance

Supervision of commissioning with test plans and documentation. Proof of the required performance parameters as the basis for acceptance and operation.

Advantages of our solution

- Procurement security: Precise tenders and structured bid comparisons reduce cost and quality risks.

- On-time implementation: Contract clarity, pre-acceptance and installation coordination stabilize milestones and start dates.

- Quality assurance: Monitoring of installation and commissioning reliably ensures functionality and performance.

- Transparency: Complete documentation and proof of performance create a clear basis for decision-making and auditability.

- Operational readiness: Coordinated interfaces and tested performance parameters enable a fast, stable production start-up.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference logistics concept for a production line for processing stainless steels at Outokumpu Nirosta GmbH

Logistics concept for a production line for processing stainless steels at Outokumpu Nirosta GmbH

Overview

Project duration: 2 months

Area: 13,475 square meters

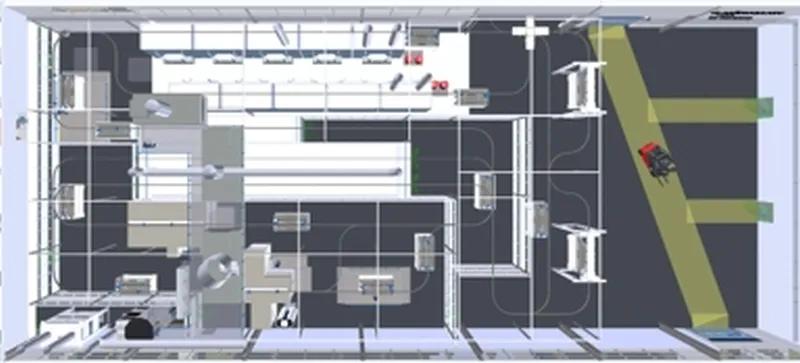

HÖRMANN Rawema Engineering & Consulting GmbH successfully developed a logistics concept for a production line for processing stainless steels for Outokumpu Nirosta GmbH. The aim was to present the plant structure and material flows transparently, to dimension areas and means of transport in a resilient manner and to define a preferred variant with a detailed layout.

Project content

Plant structure and logistics planning

Conception of the plant structure and internal logistics. Focus on short distances, stable buffers and clear transfer points.

Data collection and planning assumptions

Systematic collection of relevant data and definition of planning assumptions. Clean data as a basis for design and evaluation.

Process and material flow representation

Visualization of process and material flows along the value chain. Clear interfaces and delivery logics for smooth processes.

Dimensioning of storage areas and means of transport

Calculation of storage, transport and ancillary areas. Determination of the types and number of means of transport to ensure efficient operation.

Pre-selection of logistics equipment

Identification of suitable logistics equipment. Evaluation according to performance, integration effort and scalability.

Factory and hall structure in variants Derivation

Multiple variants of the hall and factory structure with structured comparison of variants. Decision preparation based on a list of criteria.

Detailed layout of the preferred variant

Development of the detailed layout for the selected preferred variant. Review of path relationships, storage areas and material flow quality.

Advantages of our solution

- Planning reliability: Sound dimensioning and clear planning assumptions reduce technical and operational risks.

- Increased efficiency: Optimized plant structure and material flows shorten travel times and stabilize throughput.

- Transparency: Variant comparison and detailed layout create a comprehensible basis for decision-making.

- Scalability: Pre-selected equipment and flexible space concepts support future expansion stages.

- Implementability: Early clarification of interfaces and reliable layouts speed up implementation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference General planning of new combined casting and forging line at Bharat Forge Aluminiumtechnik GmbH & Co.KG

General planning for new combined casting and forging line at Bharat Forge Aluminiumtechnik GmbH & Co.KG

Overview

Location: Brand-Erbisdorf, Saxony, Germany

Project duration: 2012-2014 + follow-up projects to date

Production area: 6.800 sqm

Investment sum: €28 million + follow-up projects

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the general planning for the new construction of a combined casting and forging line. The aim was to design the systems, logistics, layout and technical building equipment (TGA) in an integrated manner, secure approvals and control the implementation with clear project management across all trades.

Project content

System and technology planning

Planning of the production systems and technological equipment. Definition of design parameters, media connections and functional areas for stable operation.

Space dimensioning

Determination of space requirements for production, logistics and technology. Focus on efficient plant structure and scalable expansion options.

Logistics planning

Conception of internal material flows, buffers and route relationships. Ensuring an efficient supply chain from raw materials to dispatch.

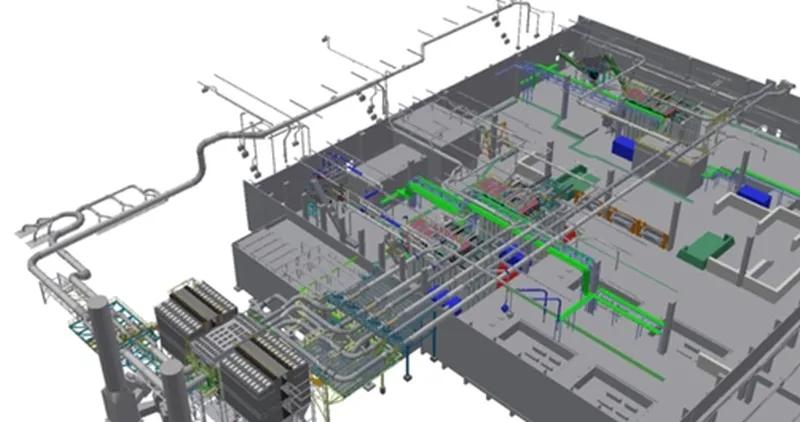

Layout design in 2D/3D

Development of a site-specific layout in 2D and 3D. Transparent visualization of installation areas, transfer points and media guides.

Interface clarification and management

Coordination of all trades with clear responsibilities. Early clarification of technical and structural dependencies reduces risks in execution and operation.

Approval planning (Federal Immission Control Act (BImSchG) and construction)

Development of approvable documents in accordance with BImSchG and building law. Accompanying the coordination with authorities until approval.

Construction and technical building equipment (TGA)

Planning service phases (LP) 1-8 according to the Fee Structure for Architects and Engineers (HOAI) Continuous planning of construction and TGA over LP 1-8 including project management and controlling of all construction trades. Structured preparation for execution with reliable documents.

Advantages of our solution

- Clear interfaces: Integrated management of plant, logistics, layout, MEP and construction minimizes technical risks.

- Approval security: Coordinated documents for BImSchG and construction accelerate procedures and increase planning security.

- Planning and implementation security: HOAI-compliant LP 1-8 with project management and controlling ensure deadlines and quality.

- Efficient plant structure: Space and logistics planning with 2D/3D layouts improves material flows and space utilization.

- Scalability: Designs and layouts can be adapted to volume fluctuations and future expansion stages.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>