Reference General planning of the new construction of the world's largest aluminum recycling plant at Novelis Europe / Novelis USA

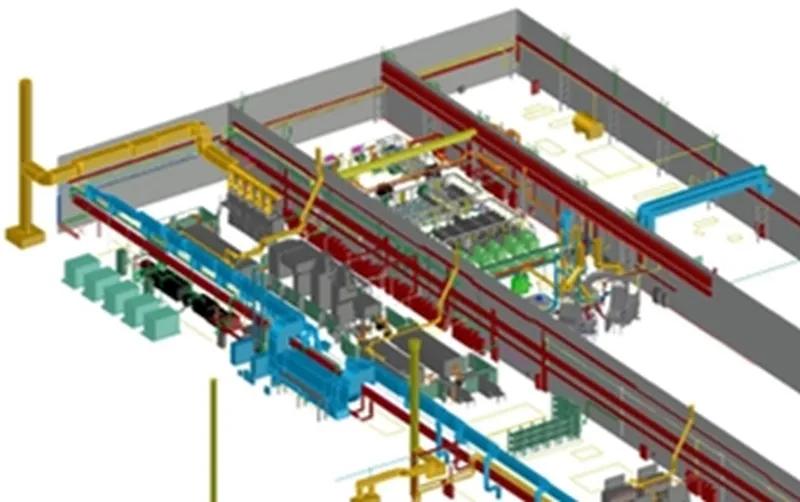

General planning for the new construction of the world's largest aluminum recycling plant at Novelis Europe / Novelis USA

Overview

Location: Nachterstedt, Saxony-Anhalt, Germany

Project duration: 2012-2015 + follow-up orders

Production area: approx. 60.000 sqm

Investment sum: over €200 million

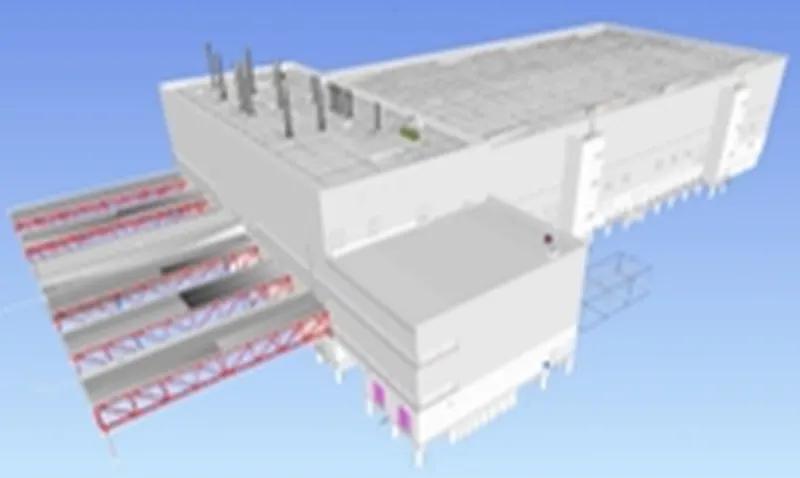

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the general planning for the new construction of the world's largest aluminum recycling plant for Novelis Europe / Novelis USA. The aim of the project was to plan processes, plants and infrastructure holistically on a greenfield site, to ensure performance through simulation and to accompany the realization including commissioning on schedule.

Project content

General planning on a greenfield site

Integrated planning of production plants, ancillary processes, buildings and technical infrastructure. Early interface clarification for smooth plant construction.

Front End Engineering Design (FEED)

Concept planning Data acquisition and analysis as the basis for the basic engineering of production equipment, ancillary processes and buildings. Derivation of reliable design parameters and functional concepts.

Engineering (Procurement) Construction Management - E(P)CM

Detailed planning, tendering and supplier selection for production equipment. Logistics planning and simulation as well as detailed layout development in 2D/3D to ensure performance.

Implementation and construction coordination

Construction supervision and coordination with clear milestones and quality checks. Close control of execution to minimize risks and rework.

Supplier and start-up management

Coordination of suppliers across all trades. Structured start-up planning for media, systems and processes up to the stable start of operations.

Commissioning support

Tests and acceptances Support during commissioning with test and acceptance plans. Proof of the required performance and quality parameters for a reliable production start.

Advantages of our solution

- Comprehensive general planning: Integration of systems, logistics, buildings and technical infrastructure reduces interface risks.

- Planning reliability: FEED and E(P)CM with 2D/3D layouts and simulations create a reliable basis for design and decisions.

- On-time implementation: Structured construction coordination, supplier control and milestone management ensure that the project runs smoothly.

- Scalability and performance: Simulation-supported logistics and layout concepts enable high throughput and future expansions.

- Clear investment: Transparent tendering and selection processes increase cost control and quality within the scope of over €200 million.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Relocation of plant and equipment for the assembly of the hood and doors of the Mercedes Benz Sprinter (T1N) at Mercedes-Benz Russia

Relocation of plant and equipment for the assembly of the hood and doors of the Mercedes Benz Sprinter (T1N) at Mercedes-Benz Russia

Overview

Location: Mercedes-Benz Russia

Project duration: 5 months

Scope of relocation: 77 equipment items in 50 packages

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the relocation of plant and equipment for the assembly of the hood and doors of the Mercedes Benz Sprinter (T1N) for Mercedes-Benz Russia. The aim was to plan and carry out disassembly, packaging and preservation, transportation with customs clearance and handover in a complete and high-quality manner.

Project content

Inventory and documentation of the assembly systems

Analysis, recording and structured documentation of the relevant assembly systems at LÄPPLE Automotive Teublitz. Creation of a reliable data basis for packaging, transportation and recommissioning.

Packaging and preservation

Planning and implementation of protective and transportation packaging, including preservation measures. Ensuring transport protection, labelling and traceability.

Transport organization and customs clearance

Coordination of transports with compliant customs clearance and complete documentation. Management of deadlines, routes and service providers through to delivery.

Relocation in two batches

Execution of the relocation of 77 equipment items in 50 packages over two batches. Structured sequencing to minimize risks and throughput times.

Handover and export documentation

Quality-compliant handover at the destination location. Ensure complete export documentation as proof of compliance and acceptance.

Advantages of our solution

- Smooth relocation: End-to-end planning and coordinated execution reduce downtime and transportation risks.

- Documentation security: Complete, quality-compliant export documentation creates traceability and auditability.

- Customs compliance: Rule-compliant processing with clear documentation minimizes delays and liability risks.

- Deadline reliability: Structured batch planning and tight supplier control ensure milestones and handover dates.

- Transparency: Consolidated intake and transport data makes decisions easier and increases project control.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference as-is analysis and concept development in compliance with AwSV at Daimler AG

Actual analysis and concept development in compliance with the AwSV at Daimler AG

Overview

Location: Esslingen a.N./Mettingen, Baden-Württemberg, Germany

Project duration: 4 months

Scope of installation: 3 cold chamber die casting machines

HÖRMANN Rawema Engineering & Consulting GmbH successfully carried out the as-is analysis and concept development for Daimler AG in compliance with the Ordinance on Installations for the Handling of Substances Hazardous to Water (AwSV). The aim was to reliably classify media and risks in accordance with AwSV, to develop compliant safety and separation concepts and to set up the documentation in a legally compliant and auditable manner.

Project content

Actual data analysis on cold chamber die casting machines

Collection and analysis of the relevant operating and process data on three cold chamber die casting machines, taking AwSV into account. Creation of a reliable data basis for derivations and measures.

Media analysis and hazard levels

Analysis of the media used and classification into hazard levels according to AwSV. Clear assignment for subsequent protection and handling concepts.

AwSV requirements and document management

Determination of regulatory requirements from the AwSV and establishment of structured document management. Ensuring traceability, completeness and up-to-dateness.

Safety concept in accordance with AwSV

Concept development for necessary safety equipment in conformity with AwSV. Definition of technical and organizational measures for safe operation.

Media separation

Concept development for the separation of water-polluting and non-water-polluting substances. Definition of storage, labelling and handling requirements to minimize risk.

Advantages of our solution

- Compliance safety: AwSV-compliant concepts and complete documentation reduce regulatory risks.

- Transparency: Structured media classification and clear derivations create traceability for technology and audits.

- Operational safety: Tailored safety and separation measures reduce the risk of failure and leaks.

- Decision basis: Concrete results per machine and area facilitate the prioritized implementation of measures.

Contact us

Interested in a tailor-made factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference relocation, camshaft production and cylinder head assembly at Daimler AG

Relocation, camshaft production and cylinder head assembly at Daimler AG

Overview

Location: Yaroslavl, Russia

Project duration: 7 months

Scope of relocation: 14 machines and conveyor technology (camshaft), 20 assembly devices (cylinder head)

Transport weight: approx. 300 tons (camshaft), approx. 100 tons (cylinder head)

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the relocation of camshaft production and cylinder head assembly from Stuttgart-Untertürkheim to Yaroslavl for Daimler AG. The aim was to smoothly plan and execute disassembly, packaging, interim storage, transportation with customs clearance, assembly and commissioning.

Project content

Relocation planning and project management

Structured planning of the end-to-end process with milestones, resources and risks. Ensuring a smooth transition from the old to the new location.

Disassembly and packaging

Proper disassembly of the systems and conveyor technology. Protective and transport packaging in accordance with technical and logistical requirements.

Interim storage and customs clearance

Organization of interim storage including inventory and status management. Customs clearance in accordance with regulations with complete documentation of the system parts.

Heavy transport and logistics

Coordination of transports for total weights of approx. 300 tons (camshaft) and approx. 100 tons (cylinder head). Planning of routes, lifting and securing measures up to delivery.

Assembly and commissioning (IBN)

Re-assembly of the machines and setting up the conveyor technology. Functional checks, test runs and acceptance preparation up to the start of production.

Interface and supplier coordination

Coordination with the trades, service providers and authorities involved. Clarification of technical interfaces and on-site implementation support.

Advantages of our solution

- Smooth relocation: End-to-end planning and coordinated implementation minimize downtime and risks.

- Deadline reliability: Clear milestones and structured project management secure the time frame.

- Compliance and customs clarity: Compliant documentation and processing reduce delays and liability risks.

- Quality assurance: Defined test and acceptance steps ensure function and performance after installation.

- Transparency: Consolidated reports and clear responsibilities increase traceability and decision-making capability.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference new SKD line (Semi-Knock-Down) at Magna Steyr Fahrzeugtechnik AG & Co. KG

New SKD line (semi-knock-down) construction at Magna Steyr Fahrzeugtechnik AG & Co. KG

Overview

Location: Graz, Styria, Austria

Scope of installation: SKD processing line with 6 workstations for painted car bodies

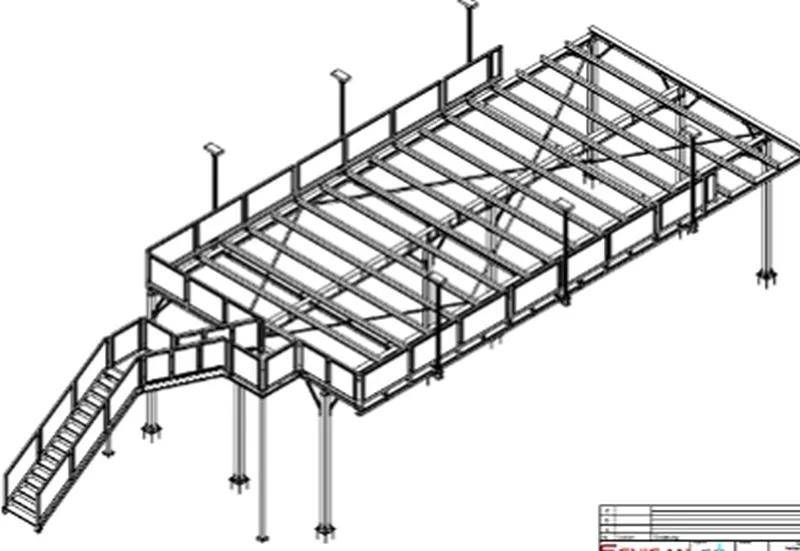

Equipment: Working platform, infrastructure, cavity preservation, conveyor technology (roller conveyors, shears, lifters, 4-point transfer unit)

HÖRMANN Rawema Engineering & Consulting GmbH has successfully implemented the new construction of a semi-knock-down (SKD)- line für Magna Steyr Fahrzeugtechnik AG & Co. KG was implemented. The aim was to plan, procure and implement a high-performance processing line with reliable functionality and to professionally prepare for commissioning and acceptance.

Project content

Processing line with six stations

Design of the work stations for cavity preservation, tooling disassembly, packaging and transfer to transport racks. Clear process sequences and transfer points for stable workflows.

System scope and conveyor technology

Integration of work platform, infrastructure and cavity preservation. Conveyor technology with roller conveyors, scissors, lifters and 4-point-transformers for efficient handling.

Concept and detailed planning

Development of the concept and detailed planning with layout in 2D/3D. Definition of interfaces, media connections and security requirements.

Tendering and award support

Preparation of tender documents, technical clarifications and tender evaluation. Structured awarding of contracts to ensure quality, deadlines and costs.

Site supervision and coordination

Coordination of implementation on site with a clear trade interface. Progress monitoring and quality assurance up to functional release.

Commissioning (IBN) and acceptance preparation

Support for IBN with test plans and documentation. Preparation of acceptance including verification of performance and safety parameters.

Advantages of our solution

- Functional reliability: Consistent concept and detailed planning with clear interfaces ensures stable processes in the SKD line.

- On-time implementation: Structured tendering, awarding and construction site coordination reduce delays and rework.

- Efficient handling: Integrated conveyor technology (roller conveyors, scissors, lifters, 4--point--transformers) reduces cycle times and improves ergonomics.

- Transparency in procurement: Precise documentation and quotation evaluation create comparability and cost control.

- Maturity of implementation: IBN support and acceptance preparation accelerate the start of production and ensure quality.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference logistics concept for an aluminum rolling mill at Novelis Deutschland GmbH

Logistics concept for an aluminum rolling mill at Novelis Deutschland GmbH

Overview

Location: Nachterstedt, Saxony-Anhalt, Germany

Project duration: 5 months

Focus: Dimensioning, process optimization, layout, simulation

HÖRMANN Rawema Engineering & Consulting GmbH successfully developed a logistics concept for an aluminium rolling mill at Novelis Deutschland GmbH. The aim was to dimension the automatic logistics system and the track infrastructure in a resilient manner, to stabilize material flows and to design shipping and scrap circulation efficiently.

Project content

Data collection Production program and logistics system

Systematic collection of the production program and the framework conditions of the automatic logistics system. Consolidated data as a basis for design and simulation

Dimensioning and simulation of the logistics system

Calculation and simulation of capacities, throughputs and buffer areas. Evaluation of expansion concepts including track systems to ensure efficiency.

Rough layout

Development of a rough layout with functional, logistics and technical areas. Clear route relationships and delivery logics for a stable material flow.

Dispatch: Dimensioning and concept planning Design of dispatch processes and areas. Development of delivery and loading concepts to ensure predictable pick-up and delivery windows.

Optimization of the scrap cycle Analysis of the scrap cycle and derivation of measures to reduce cycle times and handling costs. Integration into the overall layout and logistics processes.

Budgeting and schedule Creation of a reliable budget and schedule. Transparent basis for decisions and step-by-step implementation.

Advantages of our solution

- Planning reliability: Well-founded dimensioning and simulation create reliable capacity and throughput forecasts.

- Increased efficiency: Optimized logistics and shipping processes reduce travel times, waiting times and handling costs.

- Transparency: Rough layout and clear delivery logic make interfaces and areas visible at an early stage.

- Scalability: Expansion concepts including track systems enable a gradual increase in performance.

- Decision clarity: Budgeting and scheduling provide a reliable basis for investment and implementation decisions.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Infrastructure Planning Final Assembly BMW G30 & G/J29 at MAGNA STEYR Fahrzeugtechnik

Infrastructure planning final assembly BMW G30 & G/J29 at MAGNA STEYR Fahrzeugtechnik

Overview

Location: Graz, Styria, Austria

Project duration: 12 months

Total volume: approx. 4 million €

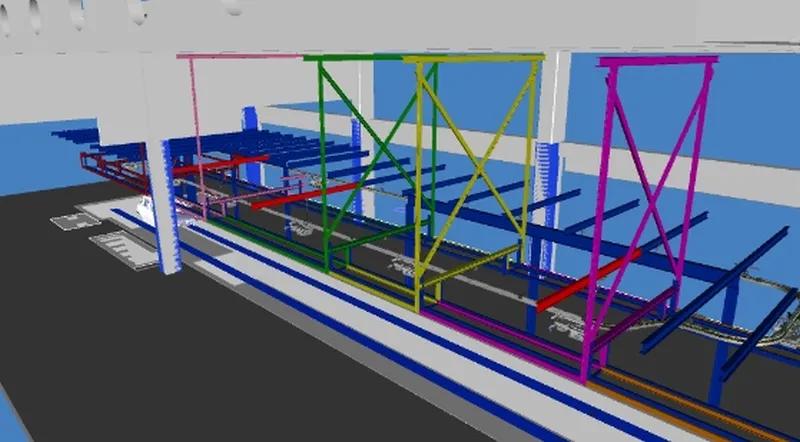

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the infrastructure planning for the final assembly of the BMW G30 and G/J29 series for MAGNA STEYR Fahrzeugtechnik. The project aimed to plan secondary and media steel construction as well as process and plant media, prepare relocations and new buildings and ensure implementation through structured tendering and coordinated supplier monitoring.

Project content

Infrastructure planning for secondary and media steel construction

Planning of secondary and media steel construction as well as process and plant media (compressed air, electrics, special media), lighting, extraction systems and social areas.

Conversion and new construction of infrastructure in assembly areas

Planning responsibility for partial conversion and new construction of infrastructure for assembly lines, pre-assembly, offline areas and plant and line supply.

Plant relocations and new builds

Preparation and coordination of plant relocations and new builds with clear interfaces and defined schedules.

Tendering, technical clarifications and tender review

Prepare tender documents, carry out technical clarifications and structured tender review. Procurement and processing of new orders.

Supplier coordination and monitoring

Supplier management and close coordination with peripheral departments during the realization phase. Ensuring quality, deadlines and interfaces.

Advantages of our solution

- Clear interfaces: Integrated planning of media steel construction, process and plant media, lighting and extraction systems reduces technical risks.

- On-time implementation: Structured tendering, tender review and supplier monitoring stabilize implementation and start dates.

- Investment transparency: Coordinated procurement and clear responsibilities ensure budget adherence in the total volume of approx. 4 million.

- Operational readiness: Planned conversions and new buildings as well as coordinated relocations enable the assembly areas to be commissioned quickly.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Hook-Up Coordination / 3D Collision Check / As-Built Documentation at Robert Bosch Semiconductor Manufacturing

Hook-up coordination / 3D collision check / as-built documentation at Robert Bosch Semiconductor Manufacturing

Overview

Location: Dresden, Saxony, Germany

Project duration: Oct. 2019 to July 2020

Total construction area: approx. 100.000 sqm

Investment sum (total): around €1 billion

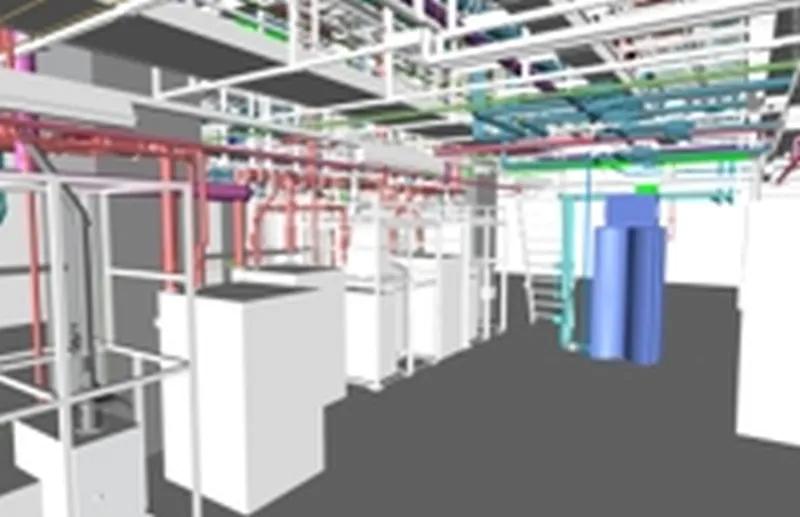

HÖRMANN Rawema Engineering & Consulting GmbH successfully supported the hook-up coordination, 3D collision check and as-built documentation for Robert Bosch Semiconductor Manufacturing. The aim was to ensure collision-free integration of the plant technology in the semiconductor and cleanroom environment, coordinate trades and interfaces and document progress transparently.

Project content

3D collision check execution planning

Check the execution planning models for collisions and interface conflicts. Early rectification to ensure smooth installation.

Construction monitoring

Continuous monitoring of execution on site. Comparison with planning statuses and ensuring high-quality implementation.

Trade and interface coordination (hook-up)

Coordination of all trades involved and their media connections in the hook-up process. Clarification of technical interfaces between the system, layout and technical infrastructure.

Progress monitoring and documentation

End-to-end monitoring of milestones with traceable documentation. Transparency regarding construction progress, acceptances and open points.

3D collision check

As-built models Validation of as-built models using 3D collision check. Comparison of actual status versus planning to ensure operational safety.

Advantages of our solution

- Collision-free: 3D checks in the execution and as-built phase minimize rework and downtime.

- Interface reliability: Structured hook-up and trade coordination clarifies media, connections and responsibilities.

- Deadline reliability: Continuous progress monitoring and clear documentation stabilize processes and milestones.

- Cleanroom compliance: Quality assurance and interface management take into account the requirements of the semiconductor and cleanroom environment.

- Transparency: Consistent as-built documents create a reliable basis for operation and subsequent changes.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference General planning of a combined casting and forging line in existing halls at Bharat Forge Aluminiumtechnik GmbH

General planning of a combined casting and forging line in existing halls at Bharat Forge Aluminiumtechnik GmbH and forging line in existing halls at Bharat Forge Aluminiumtechnik GmbH

Overview

Location: Brand-Erbisdorf, Saxony, Germany

Project duration: 2017 - 2021

Production area: 14.000 sqm

Investment sum: over €23 million

HÖRMANN Rawema Engineering & Consulting GmbH has successfully implemented the general planning of a combined casting and forging line in several existing halls for Bharat Forge Aluminiumtechnik GmbH. The aim was to plan processes and infrastructure in an integrated manner, secure approvals and implement the project on schedule over three construction phases.

Project content

Production and logistics planning

Integrated planning of production processes and material flows. Focus on stable processes, clear transfer points and efficient supply chains.

Layout design in 2D/3D

Creation of a site-specific layout in 2D and 3D. Transparent visualization of set-up areas, path relationships and media connections.

Conversion measures in existing halls (3 construction phases)

Planning and implementation of conversion measures in several halls. Skilful construction phase planning to safeguard operations and minimize downtime.

Interface clarification and management

Coordination of all trades with clear responsibilities. Early clarification of technical and structural dependencies reduces risks in execution and operation.

Approval planning (Federal Immission Control Act (BImSchG) and construction)

Development of approvable documents in accordance with BImSchG and building law. Accompanying the coordination with authorities until approval.

Construction and technical building equipment (TGA)

Planning service phases (LP) 1-8 according to the Fee Structure for Architects and Engineers (HOAI) Continuous planning of construction and TGA over LP 1-8 including project management and controlling of all execution trades. Structured preparation for execution with reliable documentation.

3D laser scanning for revision documentation

Recording of the existing building using 3D laser scanning. Provision of audit-proof documentation as a basis for operation and further measures.

Advantages of our solution

- Interface clarity: Integrated management of all trades reduces technical risks and speeds up implementation.

- Approval security: Coordinated documents for BImSchG and construction facilitate procedures and increase planning security.

- Planning and implementation security: HOAI-compliant LP 1-8 with project management and controlling ensure deadlines and quality.

- Efficient plant structure: 2D/3D layouts and production/logistics planning improve material flows and space utilization.

- Transparent documentation: 3D laser scans and revision documents create a reliable basis for operation and further planning.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference General planning for restructuring / new construction / relocation of production at Heraeus Site Operations GmbH & Co KG

General planning for restructuring / new construction / relocation of production at Heraeus Site Operations GmbH & Co KG

Overview

Location: Hanau/Kleinostheim, Hesse/Bavaria, Germany

Project duration: since 2017

Production/laboratory area: approx. 12.000 sqm Investment sum: over €80 million

HÖRMANN Rawema Engineering & Consulting GmbH has been supporting the general planning for the restructuring, new construction and relocation of production for Heraeus Site Operations GmbH & Co KG since 2017. The project aims to integrate the planning of facilities, logistics, technical building equipment (TBE) and construction, secure approvals and implement relocations smoothly.

Project content

General planning of facilities, logistics, TBE and construction

Integrated planning of all relevant trades. Interfaces are clarified at an early stage to ensure efficient and safe operation.

Determination of basic conditions, preliminary and design planning

Systematic survey of basic conditions and preparation of preliminary and design planning. Reliable basis for design, layout and investment decisions.

Involvement in approval planning (BImSchG + construction)

Support in approval planning in accordance with the Federal Immission Control Act (BImSchG) and construction law. Preparation of documents and support in coordination with authorities.

Execution planning

Detailed elaboration of the technical and structural execution. Transparent planning steps to ensure deadlines and quality.

Tendering and awarding

Preparation of tender documents and structured awarding of contracts for all trades. Comparable offers and clear service descriptions ensure cost-effectiveness.

Supplier and project monitoring

Coordination of suppliers and monitoring of execution on site. Quality assurance and risk minimization during implementation.

Relocation planning and management

Planning and management of the production relocation. Detailed relocation logistics, ramp-up concepts and safeguarding of production capability.

Advantages of our solution

- Comprehensive general planning: Integration of plant, logistics, technical building equipment (TGA) and construction reduces interface risks.

- Approval security: Involvement in BImSchG and building approvals speeds up procedures and increases planning security.

- On-time implementation: Consistent implementation planning, tendering and awarding create clear milestones and reliable processes.

- Quality and risk: Supplier and project monitoring ensures execution quality and minimizes project risks.

- Smooth relocation: Structured relocation planning and management ensure continuity and rapid stabilization of production.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>