Reference feasibility study building for test benches at AVL Deutschland GmbH

Building feasibility study for test benches at AVL Deutschland GmbH

Overview

Location: Bavaria, Germany

Project duration: 6 weeks

Constructed area: approx. 250 sqm, 3 floors

HÖRMANN Rawema Engineering & Consulting GmbH successfully carried out a feasibility study for a building with test benches for fuel cells for AVL Deutschland GmbH. The aim was to evaluate a structurally and functionally viable solution in solid construction as an alternative to the container solution, to confirm the feasibility and to provide a reliable cost framework.

Project content

Requirements for test benches for fuel cells

Evaluation and structuring of the technical and spatial requirements for the test benches. Definition of the interfaces to building and infrastructure planning.

Layout and model development in solid construction

Development of a layout design and model in solid construction as an alternative to the container solution. Creation of floor plans, sections, elevations and a 3D model to support decision-making.

Solution coordination and decision

Coordination of the structural and functional solution based on the layout. Moderation of the decision with the relevant stakeholders in the greenfield context.

Preliminary structural design and feasibility check

Preliminary structural design and technical feasibility check. Evaluation of the execution in solid construction or reinforced concrete design.

Cost framework according to DIN 276

Development of a cost framework according to DIN 276 (standard of the German Institute for Standardization). Transparent cost breakdown as a basis for further project phases.

Results report and documentation

Production of the results report including object description and feasibility statement. For reasons of confidentiality without illustrations; provision of all relevant content in text form.

Advantages of our solution

- Decision certainty: Clear feasibility statement and reliable documentation create a sound basis for implementation.

- Cost transparency: The cost framework in accordance with DIN 276 enables structured budgeting and reduces financial risks.

- Construction reliability: Structural pre-dimensioning and variant evaluation ensure technical feasibility.

- Comparability of alternatives: Layout and model development makes the differences between solid construction and container solutions visible.

- Planning basis: Complete documentation with floor plans, sections, elevations and 3D model supports the next steps of general planning.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference feasibility analysis and material flow simulation at Schwermetall-Halbzeugwerk GmbH & Co. KG

Feasibility analysis and material flow simulation at Schwermetall-Halbzeugwerk GmbH & Co. KG

Overview

Location: Stolberg, Germany

Simulation environment: 3D environment

Database: Real-time production data

HÖRMANN Rawema Engineering & Consulting GmbH has successfully carried out a feasibility analysis and material flow simulation for Schwermetall-Halbzeugwerk GmbH & Co. KG. The project aimed to conceptually evaluate an automated coil warehouse, optimize material flows and simulate the effects of changing processes in a resilient manner.

Project content

Warehouse concept for automated coil warehouse

Creation of a practical warehouse concept with clear functional areas, transfer points and interfaces. The basis for safe and scalable coil logistics.

Update, analyze and expand material flow

Update the existing material flow, analyze bottlenecks and add automated processes. Targeted dimensioning of throughputs and buffer areas.

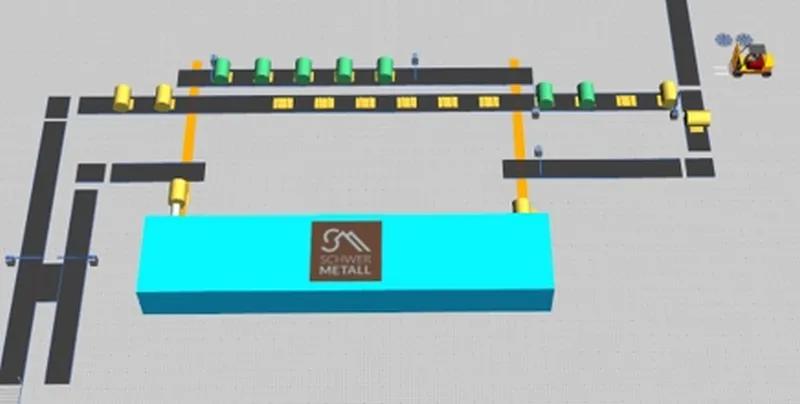

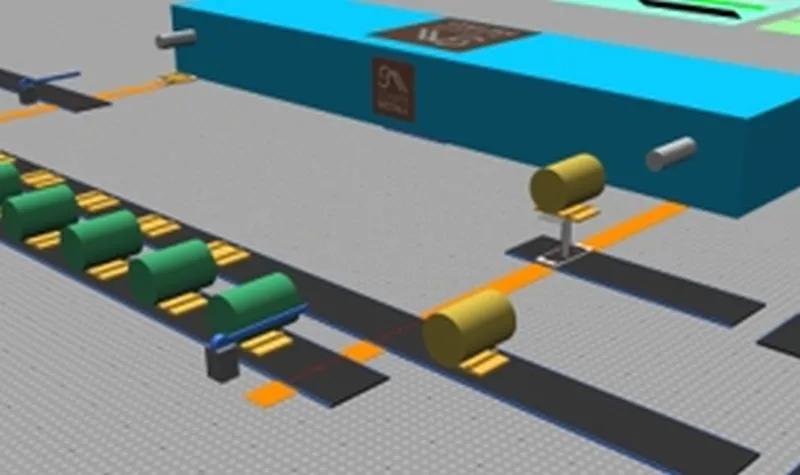

Layout variants (2D/3D)

Development of layout variants in 2D and 3D. Evaluation of path relationships, storage areas and installation conditions in the context of the hall.

Simulation of capacity, utilization and intensities

Simulation of storage capacities, utilization and handling intensities in a 3D environment. Integration of real-time production data for realistic results.

Traffic simulation and trajectories

Simulation of the traffic situation with trajectories for trucks. Safeguarding of routes, turning areas and delivery points.

Feasibility analysis of changed material flows

Evaluation of the feasibility of process changes and their impact on performance and stability. Derivation of recommendations for implementation.

Advantages of our solution

- Decision reliability: 3D simulations with real-time data create a reliable basis for variant selection and design.

- Planning reliability: Precise dimensioning of capacities and buffer areas reduces technical and operational risks.

- Increased efficiency: Optimized material flows stabilize throughput and shorten distances.

- Traffic safety: Tracking curve analyses safeguard deliveries, maneuvering areas and operations.

Contact us

Interested in a tailor-made factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

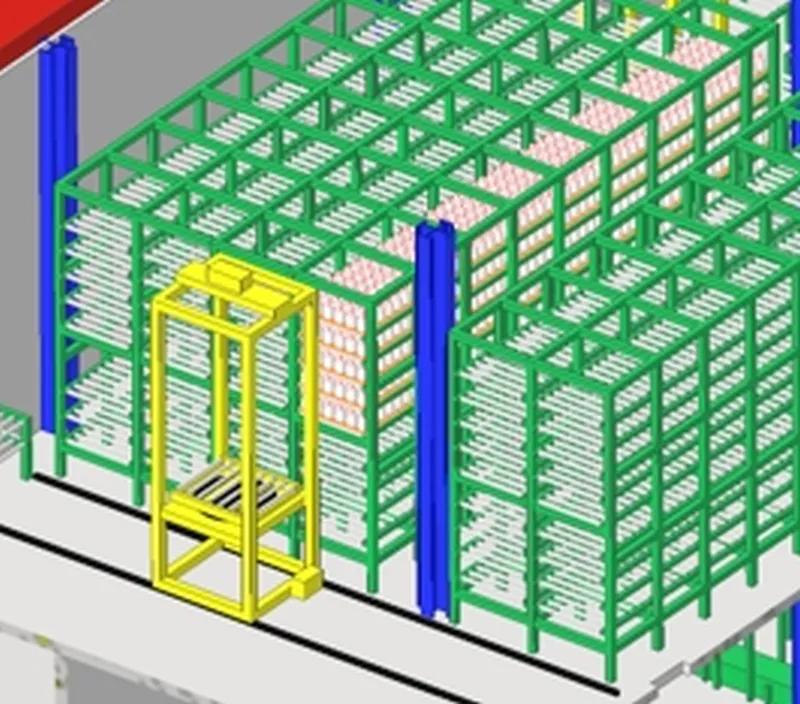

Reference Concept planning of an automatic high-bay racking system for coils at Schwermetall-Halbzeugwerk GmbH & Co. KG

Concept planning of an automatic high-bay racking system for coils at Schwermetall-Halbzeugwerk GmbH & Co. KG

Overview

Location: Stolberg, Germany

Storage area: approx. 1.800 sqm

Storage capacity: 800 coils

Maximum coil weight: 25 tons

HÖRMANN Rawema Engineering & Consulting GmbH successfully completed the concept planning for an automated high-bay racking system for coil storage for Schwermetall-Halbzeugwerk GmbH & Co. KG. The aim was to develop a resilient storage concept, optimize material flows and reliably simulate capacities and traffic situations.

Project content

Storage concept for automated coil storage

Creation of a practical storage concept with clear functional areas, transfer points and interfaces. The basis for efficient, safe and scalable coil logistics.

Update, analyze and expand material flow

Update the existing material flow, analyze bottlenecks and add automated processes. Targeted dimensioning of throughputs and buffer areas.

Optimization potential

Systematic development of optimization potential along warehouse, transport and transfer. Prioritized measures to increase efficiency and availability.

Layout variants (2D/3D)

Creation of layout variants in two dimensions (2D) and three dimensions (3D). Evaluation of route relationships, storage areas and set-up conditions in the context of the hall.

Simulation of storage capacity, capacity utilization, intensities

Simulation of storage capacities and capacity utilization including picking and handling intensities. Basis for decision-making for the dimensioning and performance of the system.

Traffic simulation and trajectories

Simulation of the traffic situation with trajectories for trucks. Safeguarding of routes, turning areas and delivery points.

Specifications and supplier management

Drafting of specifications with clear descriptions of services and interfaces. Requesting and evaluating offers for the structured selection of suitable suppliers.

Advantages of our solution

- Planning reliability: Simulated capacities and reliable layouts reduce risks in design and operation.

- Efficient material flows: Updated and expanded flow concepts shorten routes and stabilize throughput.

- Transparency: Variants and simulations create clear comparability and well-founded decisions.

- Traffic safety: Tractrix curve and traffic simulations ensure delivery and maneuvering areas.

- Supplier clarity: Precise specifications and structured evaluation strengthen quality and cost control.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

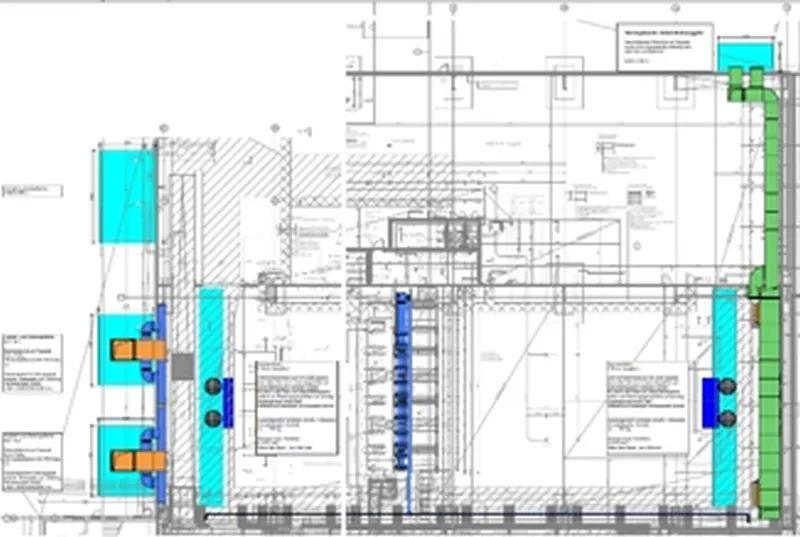

Reference comparison of neutralization systems at Novelis Deutschland GmbH - Nachterstedt plant

Variant comparison of neutralization systems at Novelis Deutschland GmbH - Nachterstedt plant

Overview

Location: Nachterstedt, Germany

Project duration: Q4/2023 - Q2/2024

Investment sum: over €2.5 million. €

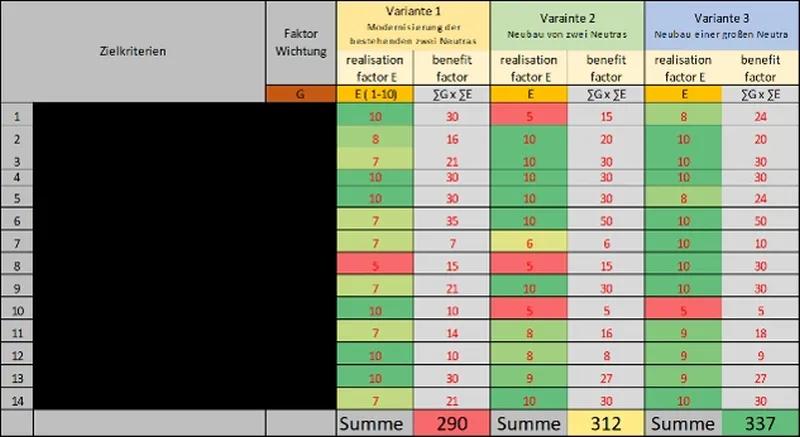

HÖRMANN Rawema Engineering & Consulting GmbH successfully carried out a comparison of variants for neutralization systems at the Nachterstedt plant. The aim was to identify the best technical and economic solution, clarify interfaces at an early stage and create a reliable basis for investment decisions.

Project content

Data collection

Systematic collection of relevant plant data, boundary conditions and requirements. Consolidation of the information as a basis for the assessment.

Determination of basic principles

Determination of technical and regulatory principles for neutralization systems. Definition of design parameters and interfaces to the technical infrastructure.

Supplier research and enquiries

Identification of suitable suppliers and preparation of clear inquiry documents. Comparison of offers according to scope of services, quality and deadlines.

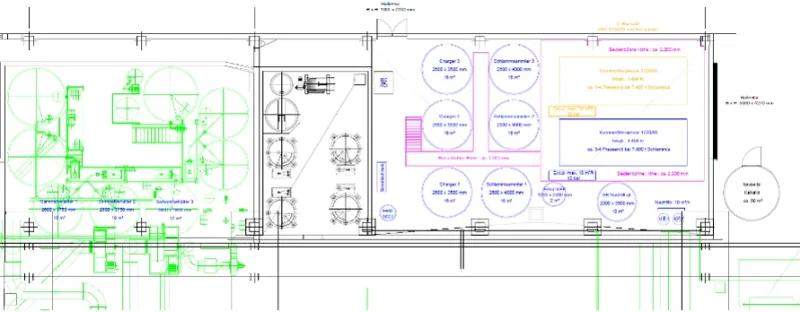

Layout planning

Development of a site-specific layout with installation areas, media connections and logistical routes. Consideration of structural requirements and interfaces to production and operations.

Variant comparison

Evaluation of several solution variants based on a catalog of criteria. Comparison of technical performance, cost-effectiveness, risks and scalability.

Budget calculation

Reliable cost estimate for investment and operation. Transparent comparison with the investment framework of over €2.5 million.

Scheduling

Creation of a realistic schedule with milestones for procurement, installation and commissioning. The basis for plannable implementation.

Advantages of our solution

- Founded basis for decision-making: Structured comparison of variants creates transparency and reduces wrong decisions.

- Cost certainty: Reliable budget calculation and investment comparison increase planning certainty.

- Date and implementation planning: Clear milestones accelerate implementation and ensure the start date.

- Interface clarity: Integrated layout and infrastructure planning minimizes risks in production, logistics and construction.

- Supplier management: Targeted research and inquiries strengthen quality and cost competition.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Recording of machine waste heat loads and testing of waste heat utilization at HÖRMANN Automotive St. Wendel GmbH

Recording of machine waste heat loads and testing of waste heat utilization at HÖRMANN Automotive St. Wendel GmbH

Overview

Location: Sankt Wendel, Saarland, Germany

Project duration: 1 month

Energy consumption: approx. 6.1 GWh

HÖRMANN Rawema Engineering & Consulting GmbH successfully carried out the recording of machine waste heat loads and the testing of waste heat utilization for HÖRMANN Automotive St. Wendel GmbH. The aim was to reliably record waste heat sources, prioritize main consumers and identify reportable systems in accordance with the Energy Efficiency Act.

Project content

Sifting through and preparing the consumer list

Structured review and preparation of the consumer list. Creation of a consistent data basis for further recording and evaluation.

Prioritization of the installations to be recorded

Evaluation and prioritization of the installations according to expected waste heat loads. Focused measurement campaign with clear priorities.

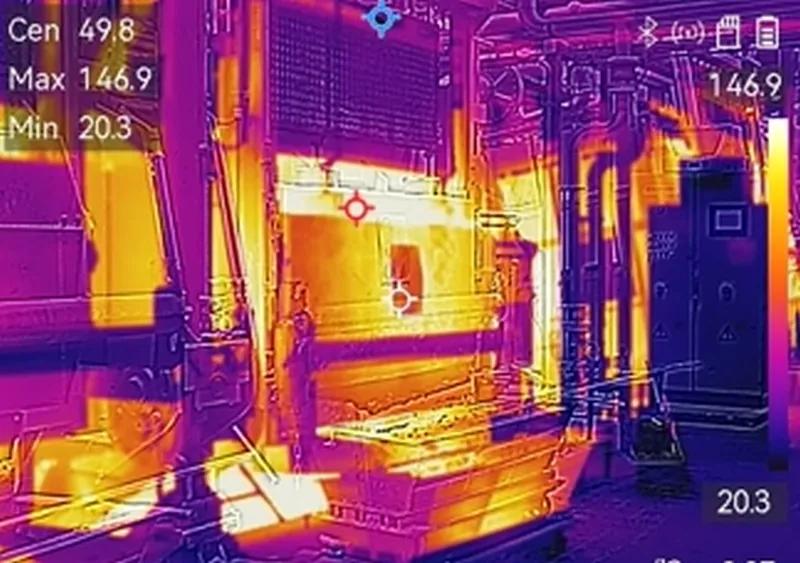

On-site recording using a thermal imaging camera

Measurement-based recording of waste heat loads directly at the installations. Identification of hotspots and verification of existing data.

Evaluation and derivation of waste heat output

Analytical evaluation of the measurement data and derivation of the waste heat output per system. Quantification of the waste heat potential with approx. 400 MWh/a as a basis for measures.

Consolidate results and prioritize main consumers

Consolidation of the results into an overall picture. Prioritization of the main waste heat consumers for targeted efficiency and utilization approaches.

Examination of waste heat utilization and regulatory reconciliation

Evaluation of possible utilization options for the recorded waste heat. Comparison of potentially reportable systems for the site in accordance with the Energy Efficiency Act.

Transparent documentation

Traceable documentation of the methodology, results and priorities. Basis for decisions and further planning steps.

Advantages of our solution

- Transparent data basis: Measurement-based recording and structured evaluation create a reliable basis for decision-making.

- Target-focused prioritization: Clear identification of the main waste heat consumers enables effective measures to be taken first.

- Regulatory compliance: Alignment with the requirements of the Energy Efficiency Act reduces compliance risks.

- Sustainability: Exploitation of waste heat potential supports resource conservation and CO₂ reduction.

- Decision certainty: Consolidated results and clear documentation accelerate implementation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference Recording and determination of waste heat loads in the entire plant near Brand-Erbisdorf

Recording and determination of the waste heat loads in the entire plant near Brand-Erbisdorf

Overview

Location: Brand-Erbisdorf, Saxony, Germany

Project duration: 52 months

Production area: approx. 26.000 square meters

HÖRMANN Rawema Engineering & Consulting GmbH successfully recorded and determined the waste heat loads in the entire plant at the Brand-Erbisdorf site. The aim was to record waste heat sources transparently, quantify loads reliably and transfer the results into a waste heat register.

Project content

Sifting through and structured preparation of the existing plant lists and technical data sheets. Creation of a reliable data basis for further evaluation.

On-site recording using a thermal imaging camera

Recording of waste heat loads directly at the plant using a thermal imaging camera. Identification of relevant hotspots and verification of the documented plant data.

Visualization of waste heat sources

Processing of the results in clear presentations. Clear overview of sources, intensities and spatial distribution of waste heat.

Evaluation by plant, area and hall

Determination of waste heat output per plant, functional area and hall. Quantification of the waste heat potential of approx. 27,000 MWh/a as a basis for evaluating measures.

Transfer to the waste heat register

Structured entry of all results in the waste heat register. Ensuring the traceability and ongoing maintenance of the data.

Data supplementation and support

Support in determining additional data required for the cadastre. Coordination with specialist departments for completeness and quality assurance.

Advantages of our solution

- Transparency: Visualized results and a structured waste heat register create a clear basis for decision-making.

- Regulatory certainty: Measurement-based verification supports compliance with the Energy Efficiency Act and other requirements.

- Targeted measures: Quantified loads per plant and hall enable prioritization of efficiency and recovery projects.

- Sustainability: Identified waste heat potential promotes resource conservation and CO₂ reduction in the plant.

- Planning reliability: Clean database reduces risks and accelerates the implementation of optimization measures.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

Reference concept for a factory for processing tropical almonds and fonio at Talmond GmbH

Concept for a factory for processing tropical almonds and fonio at Talmond GmbH

Overview

Location: Accra Region, Ghana

Project duration: two months, April - June 2025

Production area: to be roughly dimensioned in the project

HÖRMANN Rawema Engineering & Consulting GmbH successfully developed a factory concept for processing tropical almonds and fonio for Talmond GmbH. The project aimed to create a reliable basis for processes, areas, material flows, plant and personnel requirements and to prepare the implementation steps transparently.

Project content

Data collection and framework analysis

Evaluation of the current situation and relevant basics, including process data and waste heat quantities. Clean data as the basis for all further planning steps.

Develop and visualize process flows

Development and visualization of process flows along the value chain. Clear presentation of interfaces, sequences and quality requirements.

Dimensioning of space requirements

Estimation of space requirements based on planned production figures. Derivation of functional, logistics and technical areas for an efficient plant layout.

Facility and employee requirements

Dimensioning of the required facilities and employees for each process step. Focus on performance, quality and ergonomic workstations.

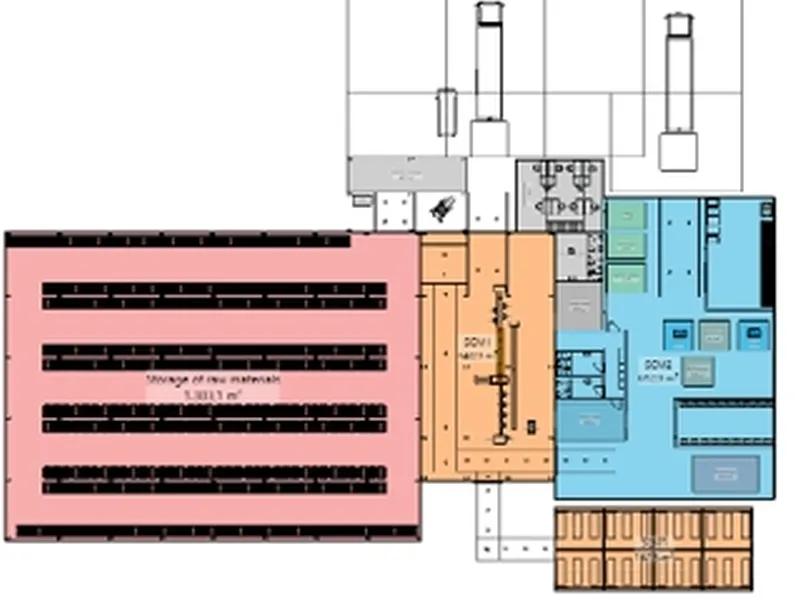

Rough layout with visTABLE (2D/3D)

Development of a rough layout for plant technology as well as logistics and functional areas using visTABLE in 2D/3D. Early visualization for the evaluation of path relationships and set-up areas.

Material flow determination

Determination of material flows with quantities, path relationships and buffer concepts. Basis for stable processes and short throughput times.

Rough cost estimate and implementation concept

Creation of a rough cost estimate with key cost drivers. Derivation of an implementation concept with prioritized steps for implementation.

Advantages of our solution

- Structured approach: Clear phases from data collection to rough layout ensure reliable decisions.

- Transparent basis for decision-making: Visualized process and material flows create understanding and comparability.

- Planning reliability: Dimensioning for areas, systems and personnel reduces risks during implementation.

- Practical relevance: visTABLE models (2D/3D) enable early validation of layout and route relationships.

- Scalability: The concept can be flexibly adapted to production volumes and expansion stages.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

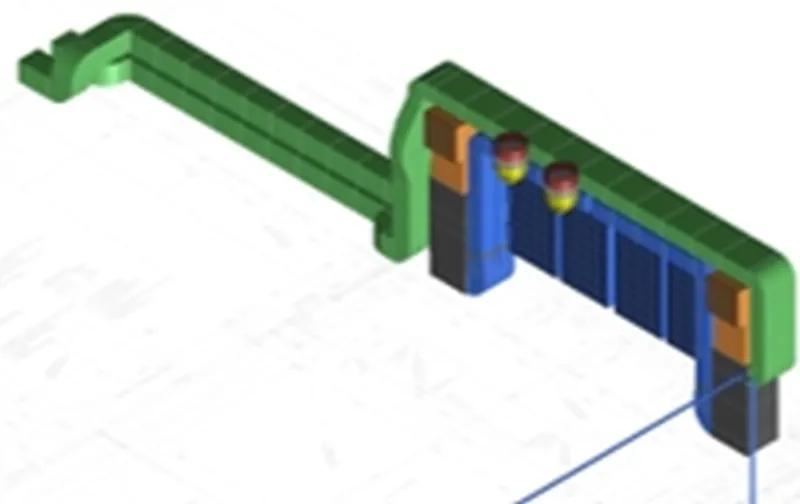

Reference planning logistics and process optimization at BELCHEM GmbH

Planning logistics and process optimization at BELCHEM GmbH

Overview

Location: Freiberg, Saxony, Germany

Project duration: 5 months

Production area: approx. 1.500 sqm

HÖRMANN Rawema Engineering & Consulting GmbH successfully implemented the planning of a logistics and process optimization for BELCHEM GmbH. The project aimed to automate yarn transport, stabilize material flows and sustainably increase efficiency in the textile environment.

Project content

Automation concept for yarn transport

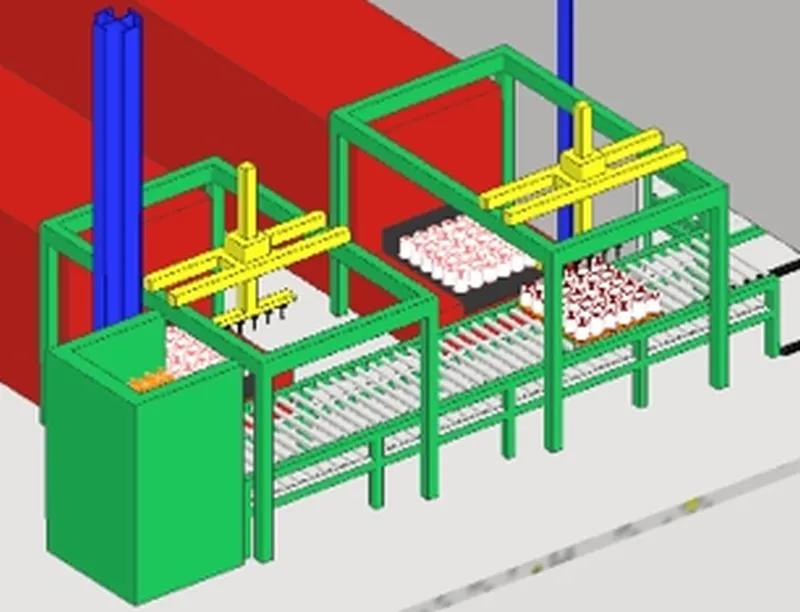

Development of a practical concept for the automation of yarn transport. Definition of requirements, transport chains and interfaces as a basis for implementation.

Automatic storage and transport systems

Conception of suitable automatic storage and transport systems. Evaluation of technologies and derivation of an integrated system for storage/retrieval and internal transport.

Integration planning for textile fiber cutting units

Planning of integration for parallel relocation of textile fiber cutting units. Design of interfaces, assembly and commissioning steps to ensure ongoing operation.

Layout planning in 2D/3D

Creation of a site-specific layout in 2D and 3D. Optimization of material flow, storage areas and path relationships in the production environment.

Special load carriers

Conception of custom-fit special load carriers. Design for textile requirements and safe, efficient handling.

Value stream analysis and automation potential

Conducting a value stream analysis for holistic process mapping. Identification of further automation potential and prioritization of measures.

Catalogue of measures, cost estimates, scheduling

Development of an implementation-oriented catalog of measures with cost estimates and scheduling. Transparent decision-making basis for step-by-step implementation.

Advantages of our solution

- Increased efficiency: Automated transports and optimized layouts reduce distances and stabilize throughput times.

- Process reliability: Standardized processes and integrated systems increase stability and quality in the textile sector.

- Scalability: Modular concepts for storage and transport systems enable adaptable expansion stages.

- Transparency: Value stream analysis, cost estimation and scheduling create clear priorities and decision-making certainty.

- Interface coordination: Sophisticated integration planning minimizes risks when relocating cutting units.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>

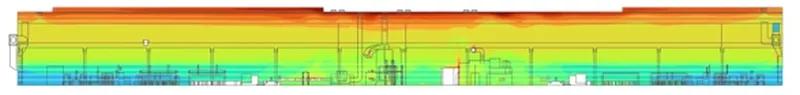

Reference Planning and simulation of a ventilation system in an existing aluminum foundry

Planning and simulation of a ventilation system in an existing building at an aluminum foundry

Overview

Location: Germany, Saxony

Project duration: 9 months

Production area: approx. 3.500 sqm

HÖRMANN Rawema Engineering & Consulting GmbH successfully carried out the planning and simulation of a ventilation system for an existing aluminum foundry. The aim of this project was to design the ventilation capacity in line with demand, efficiently dissipate waste heat and sustainably improve the air quality at the workplaces.

Project content

Actual analysis and waste heat quantities

Evaluation of the current framework conditions in the existing hall, including documentation of the waste heat and relevant process data. Among other things, a required supply air volume of approx. 184,000 m³/h and a heat output of approx. 900,000 kW were determined.

Design parameters and air changes

Calculation of the required framework parameters for the ventilation technology, including defined air change rates and volume flows. Basis for a safe and efficient design of the technical building equipment (TBE).

Ventilation and system concepts in existing buildings

Development of ventilation and system concepts based on preliminary planning, tailored precisely to the hall geometry and workstations. Consideration of material flow, heat input and structural restrictions.

Computational Fluid Dynamics (CFD) / flow simulation

Validation of concepts using flow simulations, visualization of temperature and air distribution as well as critical zones. Simulation results as a decision-making aid for variant selection and design.

Design planning of the simulated concept

Deepening of the selected concept for design planning including 3D planning. Specification of components, cable routing and installation areas for smooth implementation.

Measurement, control and regulation technology (MSR) and electrical supply

Development of a control and regulation concept and planning of the new electrical supply. Ensuring energy-efficient and reliable plant operation.

Construction planning, interfaces and project management

Coordination of construction requirements and interfaces, including cost estimates and scheduling. Transparent approach for plannable implementation.

Advantages of our solution

- Comprehensive general planning: Integrated consideration of ventilation technology, technical building equipment (TBE), measurement and control technology (MCR), electrical engineering and construction minimizes interface risks.

- Reliable design: Well-founded calculations and clearly defined framework parameters (e.g. air change) ensure needs-based dimensioning.

- Transparency through simulation: Computational Fluid Dynamics (CFD) makes flow and temperature fields visible and reduces iteration loops.

- Cost and schedule certainty: Early cost estimation and reliable scheduling create decision-making certainty for implementation.

Contact us

Interested in a customized factory planning solution for your company?

Contact our experienced team at HÖRMANN Rawema for a no-obligation consultation. >>